“If your actions inspire others to dream more, learn more, do more and become more, you are a leader.”

-John Quincy Adams

Transforming Your Supply Chain in the Digital Age: Expert Insights and Strategies

Organizations going through a Digital Supply Chain Transformation have likely appreciated increased market share, customer engagement, higher employee spirit, and expanded customer revenue. Digital Supply Chain have become a well-known approach to augment conventional Supply chain.

Digital Supply Chain have become a well-known approach to augment conventional Supply chain. On a base level, there are not many contrasts between a conventional and a Digital Supply Chain. Both include sourcing materials, transforming the material into a product, distributing the product, then selling it. Nonetheless,Digital Supply Chain can follow and finish these undertakings through computerized, digital cycles that empower more noteworthy effectiveness.

A viable Digital Supply Chain assists associations with staying aware of expanding business requests – yet many are experiencing difficulty, making and improving their Digital Supply Chain.

Handpicked for our Leaders: What exactly is Digital Transformation in 21st Century?

Traditional Supply Chain Management software experiences two basic disadvantages:

- They are compartmentalized.

- The install base is confined by old technology.

The market currently offers a couple of disruptive alternatives that eliminate the allotments among basic utilitarian storehouses. Demand, inventory, transportation, manufacturing, renewal, and fulfillment planning in one stage working with information steady across operational, strategic, and vital horizons. Besides, some offer the most recent in software innovation, supporting permeability, progressed analytics, and streamlining abilities on a similar platform.

With a Digital Supply Chain, your association should appreciate increased revenue, improved dynamic, and more agile processes. Shockingly, associations are frequently met with a grouping of difficulties once they start Supply Chain Digitalization. Let’s take a closer look at a few common challenges.

Also Read: 21 Best Digital Transformation Books

What Digital Supply Chain transformation challenges does your organization face?

The majority of organizations will say that they are still going through a Digital transformation and have more work to do. The degree of digitization changed extraordinarily among the manufacturing companies.

The top difficulties organizations face is:

- Worker Pushback

- Absence of Expertise to Lead Digitization Initiatives

- Authoritative Structure

- Absence of Overall Digitalization Strategy

- Restricted Budget

The challenges were seldom about the accessibility of technology. Only a few organizations face difficulties because current tools and technology are inadequate. The most common problems faced are due to internal factors.

Leader’s Tip:

Focus on data integration and accuracy throughout the supply chain to improve visibility and support better decision-making.

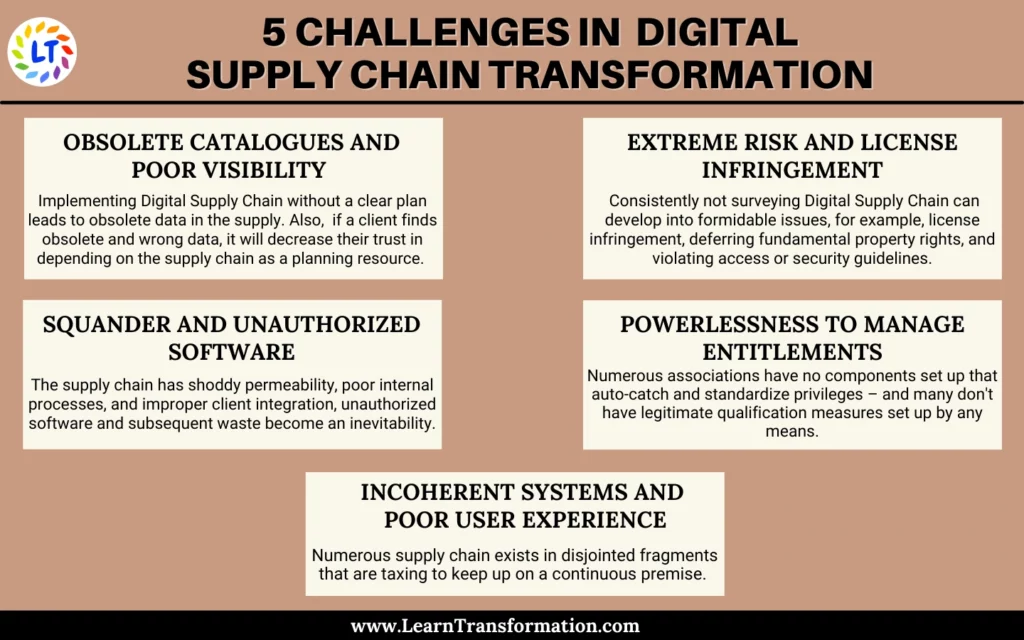

Obsolete Catalogues and Poor Visibility

A lot of organizations start implementing their Digital Supply Chain without a clear plan that empowers permeability and the convenient capturing of data. Accordingly, numerous associations do not have a solitary, global software catalogue that is frequently refreshed with precise data. This is particularly valid for estimating data. It’s significant that estimating figures are exact, accessible in numerous monetary forms, and simple to access.

In the event that data inside your supply chain is obsolete or hard to track down. Teams within your association will think that it’s difficult to appraise their innovation consumptions. Besides, if a client finds obsolete and wrong data inside the Supply Chain Transformation. It will decrease their trust in depending on the supply chain as a planning resource. It can likewise cause IT, groups, to miss significant renewal dates. Which denies them the capacity to haggle with the software maker or cancel unnecessary licenses.

The best answer for this is to improved record keeping. For bigger organizations, this frequently implies securing a Digital Supply Chain arrangement that will computerize fundamental regulatory assignments, such as recording and incorporating all purchasing related information. Moreover, it ought to have the option to separate the expense of each application in the Digital Supply Chain.

Handpicked for our Leaders: Digital Transformation & Digital Marketing is a Killer Combination

1. Squander and Unauthorized Software

At the point when a Supply Chain Digital Transformation has shoddy permeability, poor internal processes, and improper client integration, unauthorized software and subsequent waste become an inevitability.

To discover and neutralize unauthorized software, ensure that your Digital Supply Chain transformation is brought together and open to each client within your organization. This implies separating business storehouses, so every office can view and add to the Supply Chain 4.0. At that point, give combination invoicing or a division’s information bases. This will assist you with bringing in and trade information in a basic, opportune way.

2. Extreme Risk and License Infringement

Numerous associations don’t consistently survey their Digital Supply Chain to guarantee they’re meeting appropriate user rights, arrangement terms, and risk avoidance measures with new and existing contracts. This can develop into formidable issues, for example, license infringement, deferring fundamental property rights, and violating access or security guidelines.

Preventing security risks and license infringement in your Digital Supply Chain requires a software license management evaluation, ideally directed by a third party. Further, This will permit your company to decide on areas of risk, find over or underutilized software, and hinder the digital procurement of unapproved software.

3. Incoherent Systems and Poor User Experience

Numerous Digital Supply Chains don’t follow a basic, easy to use a framework. Instead, the Supply Chain exists in disjointed fragments that are taxing to keep up on a continuous premise.

This issue is far-reaching among associations – under 1 percent of organizations have incorporated software satisfaction that flawlessly integrates requesting, tagging, acquisition, contracts the executives, and delivery systems.

This absence of incorporation causes a helpless encounter for clients, which can have a broad expanding influence on the association. For instance, a client may demand software and not get a permit for quite a long time because of the absence of deftness. Meanwhile, they may download unauthorized software which causes its own host of issues.

By making a unified, centralized technique for the executives for your Digital Supply Chain Transformation, clients will appreciate a superior, more deft experience. So, This saves money on an assortment of expenses and makes work more effective for clients.

Check out the Video-

4. Powerlessness to Manage Entitlements

The most serious issue with the Digital Supply Chain is an IT group’s powerlessness to oversee existing and forthcoming permit qualifications. Numerous associations have no components set up that auto-catch and standardize privileges – and many don’t have legitimate qualification measures set up by any means.

Improperly dealing with your permit privileges accompanies a huge number of outcomes, for example, missing renditions and releases, erroneous permit types, ill-advised application connecting, and the moderate, manual formation of precise permit data.

Leader’s Tip:

To streamline operations and increase efficiency, encourage internal and external supply chain players to collaborate and communicate.

Conclusion

As a general rule, these difficulties are opportunities in a mask – by standing up to these issues in a methodical way, associations can find new occasions to support income and improve business results. However, with the sheer expansiveness of the normal Digital Supply Chain, it’s ideal to enrol the assistance of specific Digital Supply Chain software. So, This will assist you with making a viable Digital Supply Chain from the start, making an upper hand over the numerous associations whose supply chains fall short.

FAQ’s

What is Digital Transformation for Supply Chain?

Organizations going through a Digital Transformation have likely appreciated increased market share, customer engagement, higher employee spirit, and expanded customer revenue. Digital Supply Chain have become a well-known approach to augment conventional Supply chain. Digital Supply Chain can follow and finish tasks like sourcing materials, transforming the material into a product, distributing the product, then selling it through computerized, digital cycles that empower more noteworthy effectiveness.

What are 4 Key Challenges of Digital Transformation?

The top difficulties organizations face is:

- Worker Pushback

- Absence of Expertise to Lead Digitization Initiatives

- Authoritative Structure

- Absence of Overall Digitalization Strategy

- Restricted Budget

Key Takeaways

- To improve supply chain operations, increase agility, and efficiently adapt to market fluctuations, embrace digital technologies and automation.

- Deal with issues like data silos, cybersecurity dangers, hiring people, change management, and integrating legacy systems.

- To remain competitive and ensure long-term success in the digital supply chain transformation, it is important to continuously analyze developing technologies and market trends and adapt.