“Perfection is not attainable. But if we chase perfection, we can catch excellence”

Vince Lombardi

Just-in-Time (JIT) in Lean Management: Streamlining Processes for Maximum Efficiency

One of the management’s philosophies is the “Just in Time (jit) in lean management”. Management comprises the activities of an organization from setting a goal to achieving that particular goal after assessing all the obstacles and finding a solution for them. It coordinates the efforts of an organization and its employees to obtain its desired objectives within the available resources.

It is very important asset in any organization that wishes to attain profits and run an organization for a longer period. Management helps in the achievement of goals, optimum utilization of resources, lessens the cost, establishes a sound organization, provides essentials for the prosperity of the organization along with the society, thus, benefiting every aspect of an organization.

What is Just in Time (JIT) in Lean Six Sigma?

Management is an enormous word that consists of numerous philosophies and principles related to it. One of the management’s philosophies is the “Just in Time” . As the name suggests, this management philosophy calls for the production of what the customer wants, when they want it, in the quantities required by the customers, and where they want it, without being hampered in the inventory.

Just in Time management is focused on efficiency, whereas, lean management concentrates on using efficiency to add more value to the customers.

Handpicked for our Leaders: Total Quality Management (TQM)- Benefits, Examples, Principles, Elements

So rather than manufacturing large stocks of what you think the consumer may demand, by using JIT, you’ll be able to generate exactly what the customer has asked for whenever they will want it. From this method, you will able to concentrate your resources on only fulfilling what you will pay for, instead of just building large stocks of unnecessary products. With this system, each process will generate the next process that is in sequence demands.

Check this: 17 Best Business Books in the world

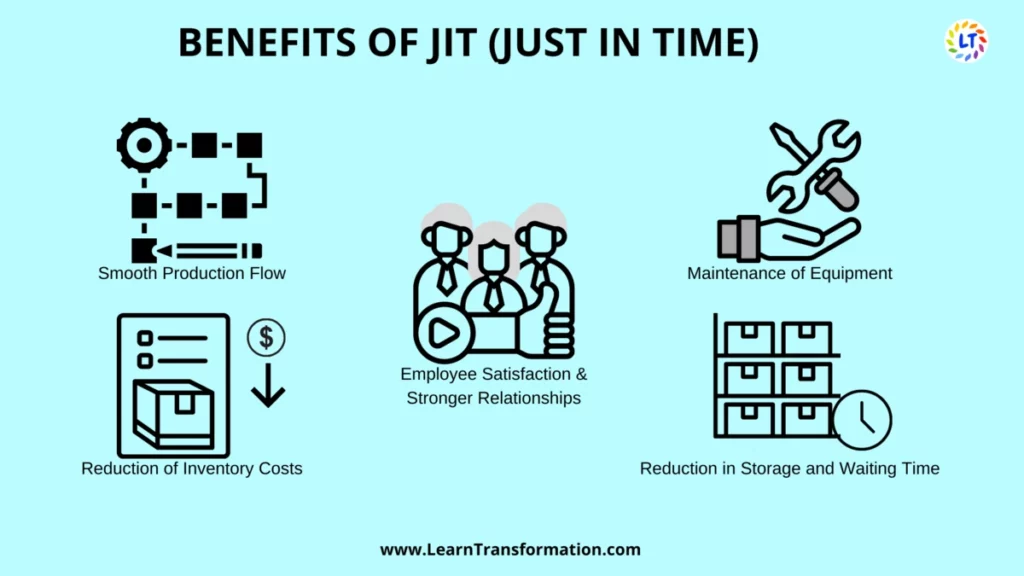

What are the Benefits of JIT?

There are five benefits of JIT written down that will help your organization to grow and flourish-

1. Reduction of Inventory Costs

The implementation of JIT aims to majorly reduce the cost of inventory by improving stock turns along with the amount of stock that is being held. JIT enables a reduction of stock up to 90% in some of the organizations and it also provides some other benefits.

2. Smooth Production Flow

This is one of the benefits that the JIT system provides. The JIT system focuses on preventing the fluctuating production rates, the arrival of the production materials from the manufacturers, delivery of final goods to the customers, and many such activities that may result in delays and extra work in the process inventories.

Also Read: Lean Mistakes – 5 Strong Reasons Why Lean Fails?

3. Reduction in Storage and Waiting Time

With the help of the JIT system, you will be able to purchase the materials and produce goods only as per the requirement, instead of building huge stocks of products for future use. It relieves the need to make space so that products and materials can behold, resulting in less time wastage. JIT also helps to encourage faster setup of production machinery.

4. Employee Satisfaction and Stronger Relationships

The JIT system facilitates multi-skilled workers, flexible facilities, and a proper atmosphere of teamwork. All these things help to improve the production system which helps the company to maintain a competitive edge in the market. It also promotes various ways to improve the product quality, achieve efficient and effective operations, along with eliminating non-value asses costs.

Check out the Video-

5. Maintenance of Equipment

The JIT management transforms the organization as it requires formal abundance to some of the routine management schedules. Important and preventive maintenance of equipment allows an organization to prevent costly downtime from machine breakdowns.

Now, you have get an idea about what the term “JIT” indicates and what are its major benefits to an organization. Further, let’s take a look at some of the valuable principles of JIT.

Leader’s Tip:

To guarantee prompt material delivery, implement efficient demand forecasts and communication channels with suppliers.

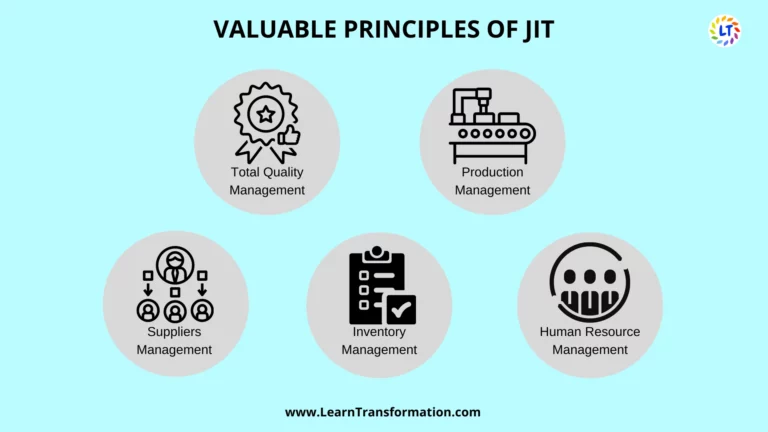

What are JIT Principles?

1- Total Quality Management

TQM consists of an organization’s wide efforts that aim to install and make a permanent climate. That will enable the employees to enhance their proficiency in the demand of products and services that customers want. This management approach focuses on long term success through satisfying customers.

In this approach, the members of the organization participate altogether for improving processes, products, cultures, and services as well.

2- Production Management

Production management, which is often called “Operations Management” involves planning and controlling. The industrial processes to ensure that those processes run smoothly at the mandatory level. Techniques that we use under this theory of management use for service and manufacturing industries as well. It concentrates on providing proper supervision and control of industrial processes related to production.

Handpicked for our Leaders: Challenges and Qualities for Lean Transformation Leaders

3- Suppliers Management

The term “Suppliers Management” refers to all the business processes and activities. That deal with the overall supplier cycle of an organization. The term is not limited to the identification, selection, and management of the suitable suppliers. But it also contributes to ensuring that their performance is at maximum value for the organization’s requirements of its third party.

Moreover, it also helps to evaluate the performance of suppliers, that if it is up to the requirements of the organization or not.

4- Inventory Management

Inventory management is a systematic approach that assists in the storage, sourcing, and selling of inventory. That contains both raw materials and finished goods. Additionally, it also means producing the right stock, at the right time, in the right place, and at the right cost.

It also comprises aspects such as controlling and overseeing the purchases thatis make from suppliers and customers. Maintaining the hold of stock, controlling the number of products that will be available for sale, and order fulfillment as well.

5- Human Resource Management

This management approach is a strategic one that effectively manages the people in an organization in a way that it can gain a competitive advantage. This approach we design to maximize the performance of employees. And taking care of all their problems, all while managing the organization as well. It is concerned with managing the people working within the organization while focusing on its policies and systems.

Handpicked for our Leaders: Key challenges & Qualities of a HR Leader

Leader’s Tip:

Processes should be constantly monitored and improved to remove bottlenecks, shorten lead times, and preserve JIT effectiveness.

Conclusion

Thus, hereby we can conclude that JIT is one of the major pillars of an organization’s lean manufacturing system. For its successful implementation, a firm base needs to build first. Also, the principles of JIT principles are equally vital for an organization’s survival as it eliminates any obstacles in the process, maximizing productivity, and eliminating bottlenecks.

FAQs

What are the five principles of JIT explain?

- Total Quality Management

- Production Management

- Suppliers Management

- Inventory Management

- Human Resource Managemen

What is JIT in principles of management?

One of the management’s philosophies is the “Just in Time (jit)”. As the name suggests itself, this management philosophy calls for the production of what the customer wants, when they want it, in the quantities required by the customers, and where they want it, without being hampered in the inventory.

Just in Time management is focused on efficiency, whereas, lean management concentrates on using efficiency to add more value to the customers.

Key Takeaways

- JIT focuses on producing and delivering goods or services exactly when they are required, hence lowering inventory levels and related expenses.

- Optimizing workflow, assuring quality at the source, retaining a flexible workforce, and encouraging continual development are all important JIT Principles.

- To quickly satisfy consumer demand, JIT implementation requires solid supplier connections, dependable logistics, and effective manufacturing techniques.