Just-in-time (JIT)may be a production strategy within which a corporation solely produces an item when a consumer has created order, thus keeping the inventories low.

Supply Chain Just In Time: Navigating the Challenges of Highly Complex Environments

IT has been a popular strategy for many years, and it has been credited with helping to improve the efficiency of many businesses. However, the recent disruptions to the global supply chain have raised questions about the effectiveness of JIT in the current environment. While this streamlined approach will prevent prices and increase potency throughout business-as-usual, it’s liable to each offer and demand shocks. So, In this article we are going to discuss the supply chain Just In Time.

It is closely related to alternative ideas like TQM, Kanban Continuous Process Improvement etc. Further, JIT aims to manufacture the precise quantities of things for the precise demand. Further, It does it by maintaining the precise quantity of inventory each on the material aspect and the finished sensible aspect.

- It aims at keeping the stock holding to a minimum resulting in an abundant lower inventory price. And, far lower storage and warehouse price.

- Minimum inventory in the slightest degree stages of the supply chain. It means less expiration as well as less wastage for the organization.

- Lower inventory means lower investment for identical levels of production. This reduces asset investment to a larger extent. This successively results in better ROI and profit for the organization.

Handpicked for our Leaders: x matrix hoshin kanri

Leader’s Tip:

To overcome the problems with JIT, modify supply chain techniques by expanding your supplier base, keeping safety stocks, and improving your forecasting skills.

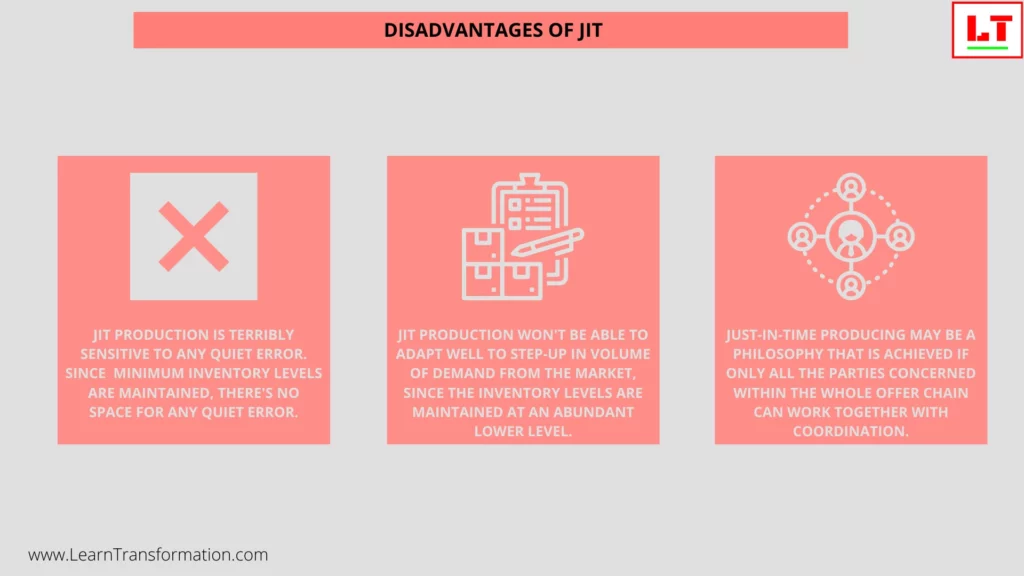

What are Disadvantages of JIT?

- It production is terribly sensitive to any quiet error. Because they maintain minimum inventory levels, there’s no space for any quiet error.

- It production won’t be able to adapt well to a step-up in volume of demand from the market since the inventory levels are maintained at an abundant lower level.

- Just-in-time producing is a philosophy that is achieved if only all the parties concerned within the whole offer chain can work together with coordination. JIT might fail someday if any of the suppliers fail to fulfil their obligations and answer the necessities in a very timely manner.

JIT may be a philosophy that proposes to attain the most with minimum inputs. We can achieve it as long as all the parties concerns within the entire system chain that commits to attaining this and work cohesively with great deal of coordination. JIT would like terribly careful designing and timely communication within the chain. The complete organization should be committed to the current philosophy.

Also Read: Amazon Air Cargo Services: How Amazon Uses It?

Leader’s Tip:

Work closely with suppliers, logistics partners, and customers to enhance supply chain visibility, communication, and responsiveness.

FAQs

What is JIT in the context of the supply chain?

JIT stands for Just-in-Time, a strategy that aims to minimize inventory by receiving goods and materials exactly when needed in the production process.

Why is JIT becoming highly difficult this year for the supply chain?

JIT is facing challenges due to disruptions caused by factors such as global supply chain disruptions, transportation issues, and fluctuating demand patterns during the year.

Key Takeaways

- Be prepared for disruptions that will affect the adoption of JIT, such as problems with the global supply chain, transportation concerns, and changing demand.

- To overcome obstacles, “consider alternative strategies like buffer inventory, safety stock, and agile supply chain practises.”

- Spend money on reliable forecasting, data analytics, and technology to improve the supply chain’s adaptability and resilience in unpredictable times.