Organisations all across the world are using the 5S technique to achieve operational excellence and continuous improvement. The 5S acronym, derived from the Japanese terms Seiri, Seiton, Seiso, Seiketsu, and Shitsuke, represents a set of guidelines that, when properly implemented, can completely transform the way your organization operates. In this blog, we’ll examine the 5S technique and all the amazing things it can accomplish for your business.

What is 5S?

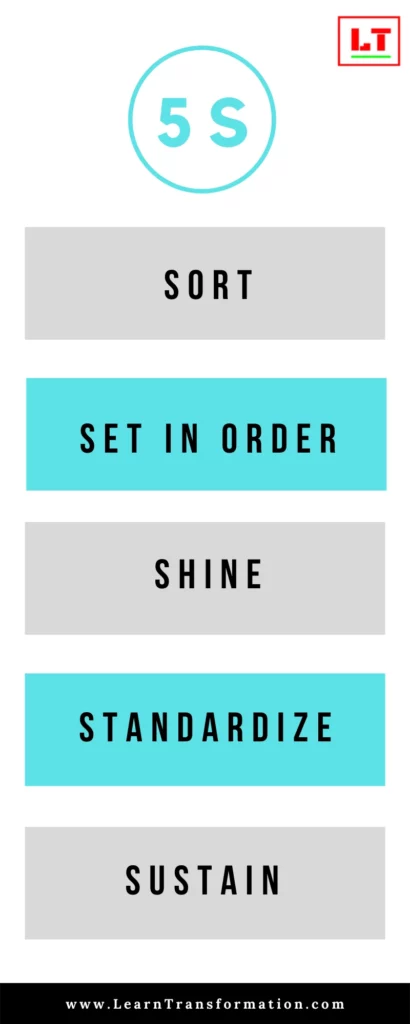

The 5S system of workplace organisation and standardisation has its roots in Japan. It derives from five Japanese syllables, all beginning with the letter “S,” and it represents a set of guidelines intended to enhance workplace productivity, safety, and organization. The 5S acronym stands for:

- Sorting all the materials and objects in a workspace into essential and non-essential categories is the first stage in the 5S methodology. Thus, the workstation clears of any unnecessary elements, leaving only those required for the current job.

- Everything that is still in the workspace is given a location and is then “set in order” (seiton). Arranging tools, materials, and equipment to make them convenient to use, easily recognizable, and accessible. Moreover, using labels and visual cues to indicate where objects belong.

- Cleanliness and hygiene are the third S in the Shine acronym. Thus, regular cleaning and maintenance activities are necessary to keep the workspace tidy and clutter-free. This not only encourages a secure and healthy workplace, but it also aids in spotting potential problems or flaws.

- Seiketsu (Standardise): Standardisation refers to the development and application of standardised business practises and operations. Thus, it ensures that the improvements made possible by the first three S’s are consistently maintained over time. Further, standardisation ensures that everyone follows the same methods and reduces variation.

- The last step is called “Sustain,” which entails keeping the advancements made via the first four S’s. It entails fostering a culture of discipline and constant improvement inside the company. Moreover, regular training, monitoring, and reinforcement are necessary to ensure that 5S practices become ingrained in the company culture.

Lean manufacturing and other process improvement approaches frequently start with the 5S method. It assists businesses with workplace optimisation, waste reduction, increased productivity, increased safety, and the development of a culture of continuous improvement. While 5S was originally developed for industrial settings, its principles have proven effective in various settings and industries, such as offices, healthcare facilities, and service organizations, to enhance productivity and organization.

Leader’s Tip

Invest in training programs to educate employees about the 5S principles and methodologies.

What are The Top Benefits of 5S?

Introducing the 5S technique into your business can have a huge number of amazing advantages. Some of the main benefits are as follows:

- Enhanced Productivity and Efficiency: The 5S method improves productivity and efficiency by removing clutter, cutting waste, and streamlining operations. Tools, supplies, and information are easier to discover by employees, which cuts down on downtime and delays.

- Cost-saving Measures: A neat workspace lessens the need for extra inventory, cuts down on equipment downtime, and lowers maintenance expenses. Savings on expenses are another benefit of waste removal.

- Improved Safety: The 5S methodology places a strong emphasis on cleanliness and organisation, which makes the workplace safer. Thus, a well-organized and regularly maintained workplace makes it easier to identify and resolve possible hazards.

- Higher Product and Service Quality: Standardised Work Processes and Organised Workspaces Contribute to This. Employees are more likely to generate high-quality results when they can concentrate on their tasks without interruptions or obstructions.

- Participating in the 5S process with employees develops a sense of pride and ownership in the workplace. A neat, orderly, and effective workstation is more likely to engage and satisfy workers.

- Space Optimisation: By effectively organising resources, businesses can make greater use of their facilities and free up valuable space. Furthermore, this may lead to lower facility expenses or the flexibility to support growth without adding on to the existing physical space.

- Having everything in its designated location enables rapid issue identification and resolution. Thus, this lessens disturbances and aids in keeping minor difficulties from turning into bigger problems.

- Cultural Shift: Lean thinking and continuous improvement can become the new norm in an organisation thanks to 5S. Thus, it promotes a culture of excellence and motivates staff to look for more effective methods of doing things.

- Environmental Benefits: By minimising waste and streamlining procedures, 5S frequently reduces resource usage and environmental impact, supporting sustainability initiatives.

- Customer satisfaction is boosted when businesses are better able to meet the demands and expectations of their customers thanks to increased efficiency and better-quality goods and services.

Also read: Lean Six Sigma Certification: Your Ticket to Career Transformation

The way work is done and how employees view their workplaces can both significantly change as a result of using the 5S technique in your company. 5S is an invaluable instrument for achieving operational excellence and maintaining continuous improvement because of these outstanding advantages.

Leader’s Tip

Ensure that senior leaders understand the value of 5S and are committed to its implementation.

How to Implement 5S?

All organisational levels must be committed to and take a methodical approach to the 5S methodology implementation. The stages to successfully implementing 5S are as follows:

- Leadership Commitment: Begin by getting senior leadership on board. Leadership needs to be aware of the advantages of 5S and promote its adoption.

- Form a 5S Team: Assemble a specialised 5S team to handle the planning, execution, and oversight of the 5S process. Thus, members of this team ought to come from all departments and levels.

- Training: Educate all staff members on the 5S tenets and practises. Moreover, make sure that everyone is aware of the goals and their responsibilities throughout the process.

- Initial Evaluation (Sort):

- To identify all products, tools, materials, and equipment in the workspace, do a preliminary assessment.

- Sort goods into essential and non-essential categories based on whether they are required for everyday work.

- Get rid of anything unnecessary from the workspace. Get rid of them, move them, or set aside a special place for them.

- Ordered in Set (Seiton):

- Allocate a particular space and storage for each necessary item.

- Label goods clearly with labels, tags, or visual clues to show where they belong.

- Make sure people who require them may quickly access the equipment and supplies.

- Gleam (seiso):

- Create a schedule and cleaning protocol for the workstation.

- Assign cleaning duties and make sure they are carried out on a regular basis.

- During the cleaning procedure, spot any potential dangers or problems and deal with them.

- Normative (Seiketsu):

- Create standardised work methods and techniques for maintaining, organising, and cleaning the workstation.

- All staff should have access to the documentation of these procedures.

- Make sure that everyone abides by the rules consistently.

- Keep going (Shitsuke):

- Make a plan for maintaining and monitoring the 5S improvements.

- To ensure the principles are followed, conduct regular audits and inspections.

- Praise and reward employees who actively contribute to maintaining these practices.

- Constant Development:

- Always look for ways to make the process itself better. Employees should actively participate in generating 5S improvement ideas.

- For a comprehensive approach to process improvement, include this into other improvement approaches like Lean or Six Sigma.

- Communication and Reaction:

- Create defined channels for employees to offer suggestions for improvement to the 5S process.

- Inform all staff members on a regular basis about the initiative’s development, highlighting achievements and addressing problems.

- Extend to Additional Areas: Consider extending the application of the 5S methodology to other areas of the company once you’ve successfully implemented the principles in one area.

- Gratitude and Compensation: Also, recognize and reward employees and teams that excel at implementing and maintaining 5S practices. Additionally, recognise their efforts and contributions.

Keep in mind that 5S is a continuous improvement process. Further, a cultural transformation is necessary to maintain a tidy, well-organized, and effective workplace. Moreover, your company can reap the amazing advantages of the 5S system by adhering to these guidelines and encouraging a dedication to its values.

Check Out : Best books On time management

Conclusion

The 5S concept can bring enormous advantages to your company’s culture, from greater productivity and cost-cutting to increased safety and employee engagement. Thus, your company can start along the path to operational excellence by adopting a disciplined approach and encouraging a commitment to the 5S principles. Why then wait? Start your 5S journey right away and see the transformational impact it can have on your business.

Key takeaways

- In order to boost productivity and shorten lead times, 5S encourages waste-free operations and waste reduction.

- By implementing 5S, you may cut down on wasteful expenses like maintenance, downtime, and superfluous inventory.

- A safe environment is made possible by a well-organized workstation, which can identify and reduce potential risks.

FAQs

What are the benefits of 5S in an organization?

The 5S methodology offers several significant benefits to organizations. It enhances productivity and efficiency by decluttering workspaces and optimizing operations, resulting in reduced downtime. Additionally, it introduces cost-saving measures by minimizing excess inventory, reducing equipment downtime, and lowering maintenance costs. Furthermore, 5S improves workplace safety by emphasizing cleanliness and organization, making it easier to identify and address potential hazards.

How do you implement 5S in your organization?

To successfully implement the 5S methodology, a systematic approach involving commitment from all organizational levels is essential. The key steps include securing leadership commitment, forming a dedicated 5S team with representation across departments, and providing comprehensive training to ensure that all employees understand the 5S principles and their roles in the process.

Also check out: