Leadership is the capacity to translate vision into reality.

Warren Bennis

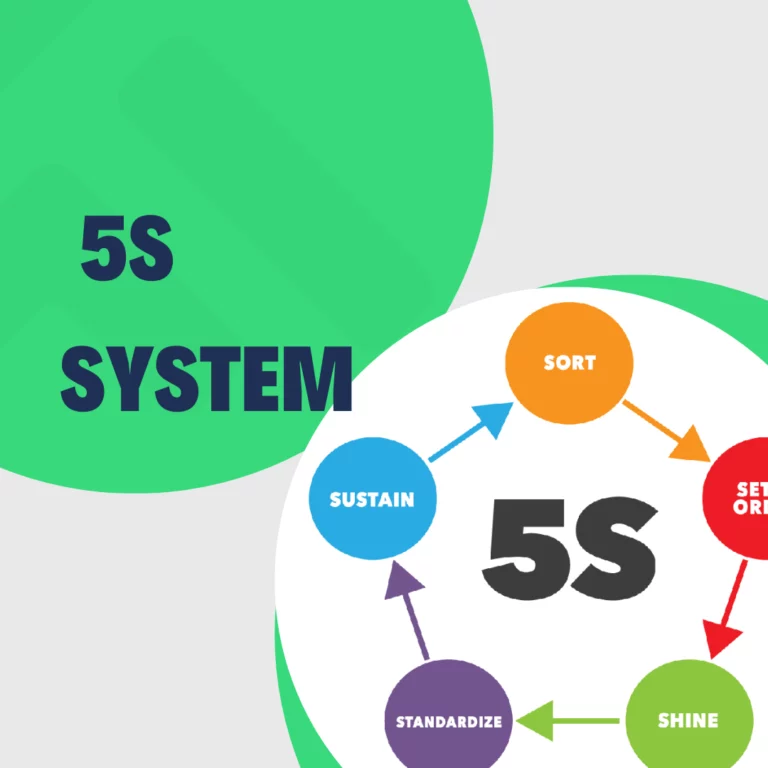

Sort, Straighten, Shine, Standardize, and Sustain are the five steps in the 5S process for creating a more orderly and effective workspace. Thus, advanced lean manufacturing tools and procedures can be implemented on top of 5S. What is 5S System? The 5S system of visual management is systematic and makes use of everything from floor tape to operations manuals. It’s not just about keeping things tidy and organized; it’s also about increasing productivity and profit. Moreover, the 5S framework places an emphasis on using a particular attitude and set of tools to boost productivity and value. It entails performing waste removal exercises as well as monitoring, evaluating, working together, and searching for garbage.

Unlock a world of knowledge with just one click: Navigating Lean Digital Transformation

What is 5S System?

Five Japanese terms that identify each step of the process are referred to as “5S” in this context. The definitions of the five Ss are as follows:

- Sort (Seiri): In this process, superfluous items are sorted and removed from the workplace. Thus, it facilitates the removal of clutter and makes the atmosphere more organised and effective.

- Set in Order (Seiton): In this stage, the required materials are logically ordered and organised. Everything has a specific place, which makes it simpler to locate and use objects when needed.

- Shine (Seiso):In this step, focus is given to upkeep and cleanliness. Further, employees conduct regular and thorough cleaning to maintain an orderly and visually pleasing workplace.

- Standardise (Seiketsu): To preserve the first three S’s, standardisation entails creating and putting into place clear procedures, norms, and visual controls. Thus, it guarantees consistency and aids in maintaining the advancements made.

- Maintain (Shitsuke): The last step entails developing a continuous improvement culture. Hence, it entails encouraging employees to adhere to the 5S principles with discipline and dedication by incorporating them into everyday work routines and habits.

Beyond the manufacturing industry, offices, healthcare settings, and service-related jobs can utilize it. Moreover, the Lean Six Sigma methodology is well known for its methodical approach to process improvement, which aims to reduce waste and increase productivity. Thus, the 5S system is one of the fundamental instruments used in this methodology. Additionally, the 5S approach, which originated from Japanese industrial techniques, offers a disciplined framework for setting up the workplace, eliminating clutter, and boosting productivity. We will examine the fundamentals of the 5S system and how Lean Six Sigma relies on it in this blog post.

Also read: Convert Traditional Company to a Lean Transformation Company

What Is the 5S System?

A organised methodology for workplace efficiency and organisation is the 5S System. It is frequently utilised in Lean manufacturing and Lean Six Sigma techniques and has its roots in Japan. The name “5S” comes from five Japanese words that each begin with the letter “S,” and they stand for the main procedures in the system. An outline of each of the 5S principles is given below:

- Sort (Seiri):In this step, you sort all materials and objects in a workspace to identify what’s necessary and what’s extraneous. After removing or disposing of unnecessary items, only the ones essential for ongoing work processes remain.

- Set in Order (Seiton): Following sorting, the essential elements must be meticulously arranged and organized. Everything has a location, so it’s simple for employees to locate what they need right away. This idea emphasises effectiveness and cutting down on time wasted looking for supplies or tools.

- Shine (Seiso): The “Shine” tenet places a strong emphasis on maintaining a tidy workspace. Maintaining a tidy workplace involves continuous cleaning. A safe, well-lit workspace improves visual management, equipment longevity, and safety.

- Standardise (Seiketsu): Establishing clear standards and rules is necessary to maintain the first three S’s (Sort, Set in Order, Shine). These requirements guarantee that the workplace will always be tidy and effective. Standardisation aids in preventing the return of chaos.

- Maintain (Shitsuke): The fifth and final “S” emphasises maintaining the advancements established by the 5S system. Ensuring the 5S principles become ingrained habits, not one-time efforts, involves continuous monitoring, regular audits, and employee training.

Leader’s Tip

Secure leadership buy-in and commitment to the 5S implementation.

The 5S System aims to organise things while also fostering a culture of cleanliness, orderliness, and efficiency in the workplace. It contributes to waste reduction, safety enhancement, product quality improvement, and general productivity growth. Although rooted in manufacturing, the 5S concepts have effectively adapted and found use in various workplace settings, including offices, healthcare facilities, and service environments.

How Does the 5S System Benefit Lean Six Sigma?

Lean Six Sigma can benefit significantly from the 5S System, which makes it a useful tool for process improvement and waste reduction. Here are some advantages of the 5S System for Lean Six Sigma:

- Waste Reduction: A key component of Lean Six Sigma is the identification and elimination of waste in processes. The “Sort” stage of the 5S System, in particular, aids businesses in identifying and clearing clutter and pointless items from the workplace. Lean Six Sigma’s waste reduction objectives align perfectly with reducing physical waste.

- Efficiency Gain: The 5S System promotes a clutter-free and orderly environment. Efficiency in operations improves, reducing the time spent searching for supplies, information, or tools. The 5S System is essential to achieving the process efficiency goals of Lean Six Sigma.

- Visual cues such as labels, color coding, and clear signage are some examples of visual management in the 5S System. These visual management strategies support Lean Six Sigma’s emphasis on visual controls and process standardisation by making it simpler for staff members to comprehend and adhere to standardised procedures.

- Quality Improvement: Errors and defects are less likely to occur in a neat and organised environment. The “Shine” principle of the 5S System ensures well-maintenance of tools and equipment, reducing the risk of malfunctions leading to defects. This immediately supports the focus of Lean Six Sigma on raising the calibre of products and services.

- Employee Engagement: Involving staff members in the 5S process generates a sense of pride and ownership in the workplace. Lean Six Sigma emphasises the importance of empowered, engaged personnel who actively contribute to process improvement initiatives.

- The “Standardize” phase of the 5S System formalizes sorting, organizing, and shining procedures. This standardisation makes sure that the enhancements are not just band-aid solutions but rather engrained behaviours. Lean Six Sigma places a strong emphasis on standardisation as a means of preserving process consistency.

- Enhancement of Safety: A spotless and well-organized workplace increases safety. The 5S System encourages safety by minimising dangers and clutter. Lean Six Sigma prioritizes safety for enhanced efficiency and productivity.

- The “Sustain” stage of the 5S System enables continuous monitoring and maintenance of the improvements. Lean Six Sigma places a strong emphasis on sustainability, emphasising the process improvements’ long-term durability.

In conclusion, the 5S System enhances Lean Six Sigma by offering a standardised method for workplace efficiency. Waste reduction, process efficiency, quality enhancement, and staff engagement align with Lean Six Sigma goals. Properly integrated, the 5S System is a vital tool in Lean Six Sigma for operational excellence.

Also read: Great 8 Thinkers in the History of Lean

How does the 5S system fit into lean tools?

The 5S System, fundamental in Lean practices, promotes workplace efficiency, organization, and continuous improvement. The 5S System is, in essence, not simply a solo tool but a crucial component of Lean tools and thinking. Thus, by establishing an organised, effective, and visual workplace—essential for discovering and removing waste, enhancing processes, and attaining Lean‘s goals of effectiveness, quality, and customer satisfaction—it lays the foundation for the implementation of Lean.

3 Best 5S Books

Global Reader’s Click Below:

- Good Leaders Ask Great Questions: Your Foundation for Successful Leadership

- The Self-Aware Leader: Play to Your Strengths, Unleash Your Team

- 5S Made Easy: A Step-by-Step Guide to Implementing and Sustaining Your 5S Program

India Reader’s Click below:

- Lean – Kaizen – Kanban: Six Sigma – Startup – Enterprise – Analytics 5s Methodologies. Exploits Kaizen System for Perpetual Improvement. Exploits … as a Key to High-Performance Productiv

- 5S Made Easy: A Step-by-Step Guide to Implementing and Sustaining Your 5S Program

- Improving the Extended Value Stream: Lean for the Entire Supply Chain

Conclusion

In conclusion, the Lean Six Sigma 5S System is much more than just a system for organising your workspace; it is a conceptual framework that embraces the ideas of effectiveness, waste reduction, and continuous development. Originating from Japanese practices, the 5S System guides businesses with five core principles: sort, set in order, shine, standardize, and sustain.

In order to achieve operational excellence, reduce waste, increase efficiency, and promote a culture of continuous improvement, the 5S System and Lean Six Sigma work together to offer a holistic strategy. Furthermore, the 5S System guides Lean Six Sigma to process perfection and customer satisfaction, fostering excellence.

The Lean Six Sigma methodology uses the 5S system as a fundamental tool, which helps to cut waste, enhance quality, and streamline processes. Thus, organisations can establish an environment where people feel empowered to actively contribute to process improvement by embracing the concepts of Sort, Set in Order, Shine, Standardise, and Sustain. Hence, the 5S system continues to be an essential component of firms’ Lean Six Sigma toolkits as they pursue excellence and continuous improvement.

Key takeaways

- Five concepts make up the 5S System, a structured methodology for workplace efficiency and organisation: sort, set in order, shine, standardise, and sustain.

- The 5S System is a commonly used tool in lean manufacturing and lean six sigma techniques that has its roots in Japan.

- Waste reduction is one of its main objectives, which perfectly complements Lean Six Sigma’s goal of getting rid of waste from processes.

FAQs

How does the 5S system fit into lean tools?

The 5S System is a cornerstone of Lean tools and processes and is essential for fostering workplace efficiency, organisation, and continuous improvement. The 5S System is, in essence, not simply a solo tool but a crucial component of Lean tools and thinking. By establishing an organised, effective, and visual workplace—essential for discovering and removing waste, enhancing processes, and attaining Lean’s goals of effectiveness, quality, and customer satisfaction—it lays the foundation for the implementation of Lean.

What is 5S Lean Six Sigma?

The Lean Six Sigma 5S System is much more than just a system for organising your workspace; it is a conceptual framework that embraces the ideas of effectiveness, waste reduction, and continuous development. The 5S System, which has its roots in Japanese procedures, directs businesses using five fundamental ideas: sort, set in order, shine, standardise, and sustain.