“Without data, you’re just another person with an opinion”

W. Edwards Deming

Revolutionize Your Supply Chain with a Transformation Strategy

The supply Chain Transformation Process is a wrap of the entire effort needed to transform Supply Chain functions to shine in the digital world to support the requirements of an omnichannel world. The supply chain has been throughout since people realized they had things worth trading. It’s a riveting time in the supply chain.

Furhtermore, There are a lot of interesting technologies appearing together to generate new possibilities, and dynamic new ways of doing business and meeting customer requirements, technologies like blockchain, IoT, Machine learning, and artificial intelligence. So, A supply chain contains all the businesses & individual contributors involved in developing a product, from raw materials to completed merchandise.

Subsequently, the transformation has been & remains an important feature of the supply chain. Moreover, In today’s modern world, the supply chain is an all-around ecosystem connecting product development, manufacturing & distribution networks into one completely transparent & digitized system.

Supply chains transformed with new technologies to obtain benefit of these technologies. These technologies are making it simpler than ever to digital supply chain transformation and manage complex supply chains more efficiently to attain higher service levels at lower costs.

With the rush of online ordering, disturbance of inventory availability & new environmental pressures put forward on by the coronavirus pandemic, businesses across industries are taking an analytic look at the health & maturity of their supply chains to make sure they can resist both present as well as future demands. Hence, The transformation journey can be developed over time by determining areas of enhancement that will help an organization reach its desired objectives.

- Revolutionize Your Supply Chain with a Transformation Strategy

- Supply Chain Transformation Requirements

- All you need to know about Amazon’s Supply Chain Transformation Strategy-

- How to drive Supply Chain Transformation?

- Supply chain transformation Importance

- What are the 5 main supply chain transformation processes?

Supply Chain Transformation Requirements

Most businesses succeed when correct balance between people, processes & technologies is attained.

1. People:

Supply chain transformation roadmap has turned into a human-centered model, in which a sequenced approach of siloed operations moved to a flexible network of participants & partnerships that will qualify supple as well as adaptable supply chain operations.

2. Processes:

Get your processes right & then see how technology can make them even better.

3. Technology:

Although supply chain processes still engage procurement, manufacturing, and logistics, emerging technologies are enormously impacting how these processes are implemented.

4. Cognitive Computing:

Cognitive technologies are necessary for making sense of the oceans of data being generated each & every day by connected systems. These technologies automate the statistical expert’s & data expert’s knowledge, so the ideation cycle can be enormously shortened & more vision can be auto generated during transformation.

5. Robotics & Automation:

Robotic Process Automation (RPA) decreases costs as well as errors. Moreover, The transportation industry’s interest is shifting towards autonomous vehicles. Hence, Experiments with truck platoons (three vehicles, one manned and two autonomous) are currently being conducted in North Carolina.

Also See: Supply Chain 4.0 & Logistics 4.0: The Major Difference

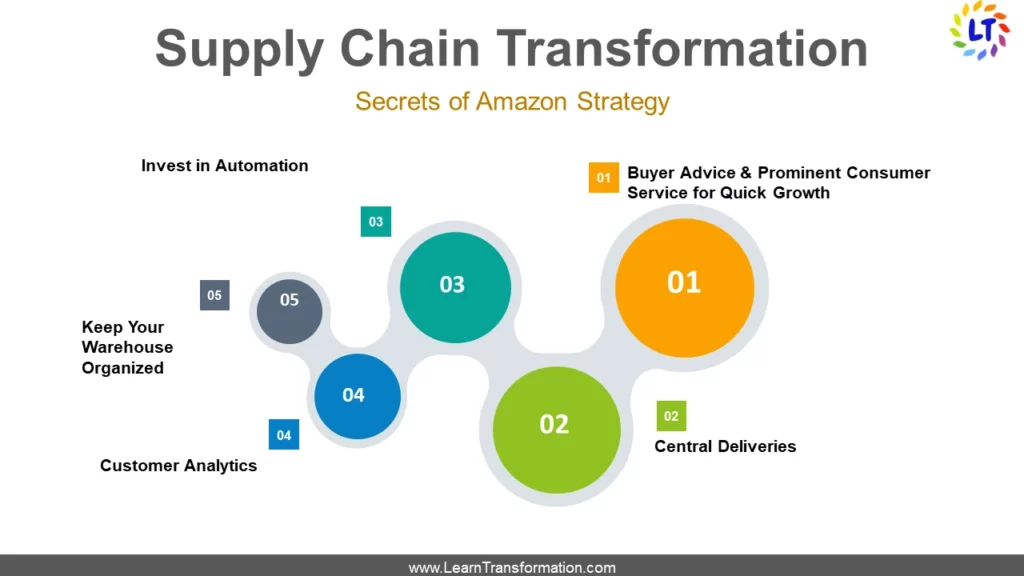

All you need to know about Amazon’s Supply Chain Transformation Strategy-

Amazon has become the leading online marketplace in the world. The company has become one of the quickest growing in history, due to its complete restructuring of the supply chain digitization strategy. Supply chain digitization strategy. It’s all part of a winning supply chain strategy that’s revolutionized the eCommerce business & increased customer expectations.

So, Let’s Learn here, how to create & implement a winning supply chain transformation strategy.

1. Buyer Advice & Prominent Consumer Service for Quick Growth:

Amazon has been enjoying a period of quick growth over the last few years. Moreover, The company keeps delivering increasingly products through the digital supply chain transformation, satisfying the customers at every turn. So, The better you serve your customers, the quicker your supply chain will rise.

2. Central Deliveries:

Amazon is known for its Prime service, offering free, 2 day shipping to its most loyal customers. Amazon has also introduced Counter to provide a “Buy-Online, Pickup In-Store” (BOPIS) strategy since Amazon doesn’t have many physical locations.

3. Invest in Automation for supply chain transformation

If you want to compete with the best of the best when it comes to logistics, then there is need to invest in automation. These machines will make your complete supply chain more effective. Because, these can work 24/7 without taking a break, so you can amplify efficiency without overworking your employees. Hence, If you’re beginning with warehouse automation, figure out small ways to automate particular aspects of your business.

4. Customer Analytics:

Amazon utilizes data analytics to predict their customers’ future buying habits. They send the products their consumers are most probably to buy to local distribution centers so they can be delivered as swiftly as possible once the customer decides to purchase. Hence, It’s called predictive shipping in VUCA. In addition to this, Amazon gathers all of user’s data, including their buying history, what items they view & keep in their shopping cart what type of products will be most famous with consumers in a given geographic location. So, Keep your distribution centers stocked with famous products & determine which products your customers are most probably to buy.

5. Keep Your Warehouse Organized:

Keep your warehouse organized with industrial storage bins, stack racks & other storage equipment. Make sure all your items are easily accessible and keep the most famous items close to the loading dock.

Also See: 5 Most Important steps towards Profitable Supply Chain Transformation.

Leader’s Tip:

To increase effectiveness and responsiveness, encourage collaboration and communication throughout the whole supply chain ecosystem.

How to drive Supply Chain Transformation?

1. Machine Learning & AI Enhanced Planning-

Planning is an area where more customers will look to leverage AI. Further, The key capability requirements for next generation planning that can use AI efficiently comprises: The need for decisions to be made at the transaction layer in supply chain transformation process.

This is where autonomous agent makes decisions depending on real-time transactional input. For instance, in the manner, Uber meets supply to demand in real time that turned the cab industry head over heels.

2. Empowering Inventory Visibility-

Consumer call for swift delivery times & easy, real-time tracking methods has been intensified under present circumstances, persuading companies’ inventory visibility & management. Inventory is no longer just in the warehouse. It’s everywhere now, from trucks and trains to sorting facilities and delivery vehicles, making it more difficult to track.

Businesses can promote inventory visibility over all areas of the supply chain digitization strategy by developing systems from the edge & working inward. Thus swifter & more precisely the business can collect information from the service point. Technologies like sensors, RFID & portals help companies to gather more data on their inventory & supply chain transformation process supplying to data-driven decisions and increased efficiencies across the complete operation.

Best Video for you-

3. Enhancing Performance with Digital Technologies-

Advancement in digital technologies have enabled many companies to enhance their supply-chain digitization performance over time. Companies that develop a transformation roadmap with the sight of consistent innovation & improvement have the potential to unbolt the full ability of their supply chains.

4. Looking & Keeping Talent for New Technologies-

New technologies need new skills, of which there’s a distinct shortage right now. Companies which train their employees or attract the right talent with these skills, will have a unique advantage as we shift towards these machine learning and artificial intelligence driven paradigms.

Supply chain transformation Importance

Supply chain transformation is becoming increasingly important for organizations due to the impact it can have on business operations and bottom-line profitability. Here are some reasons why supply chain transformation is crucial:

Improved efficiency: Supply chain transformation can help organizations streamline processes, reduce waste and optimize inventory levels, leading to improved efficiency and reduced costs.

Enhanced customer service: With supply chain transformation, organizations can improve their order fulfillment processes, reduce delivery times, and offer greater product visibility to customers. This can lead to improved customer satisfaction and loyalty.

Increased agility: In today’s rapidly changing business environment, supply chain agility is essential for organizations to remain competitive. A transformed supply chain can help organizations respond quickly to market changes, supply chain disruptions and customer demands.

Better risk management: Supply chain transformation can help organizations identify and mitigate risks in their supply chain, such as supplier disruptions, quality issues, and compliance risks.

Innovation and growth: A transformed supply chain can help organizations innovate and introduce new products to the market faster, leading to increased revenue and market share.

Overall, supply chain transformation can enable organizations to optimize their operations, improve customer service, increase agility and mitigate risk, leading to better financial performance and growth opportunities.

Check Out This also: 17 Best Business Books in the world

What are the 5 main supply chain transformation processes?

So, The five main supply chain processes are:

Plan: This process involves forecasting demand, creating a supply plan, and setting performance metrics. It helps organizations align their supply chain with their business goals and objectives.

Source: This process involves identifying and selecting suppliers, negotiating contracts, and managing relationships. It helps organizations ensure a reliable supply of goods and services at the right cost and quality.

Make: This process involves manufacturing and assembling products based on the demand forecast and supply plan. It helps organizations optimize their production processes, reduce waste, and improve product quality.

Deliver: This process involves transporting and delivering products to customers. It helps organizations ensure timely and efficient delivery, track shipments, and manage customer expectations.

Return: This process involves managing product returns, repairs, and replacements. It helps organizations manage reverse logistics, minimize costs, and maintain customer satisfaction.

These five supply chain processes are interconnected and must work seamlessly to ensure efficient and effective supply chain operations.

Leader’s Tip:

Adopt digital technologies like IoT, AI, and blockchain to improve the agility, visibility, and tracking of your supply chain.

Final Word

Doesn’t matter where a business is in its supply chain transformation journey, above mentioned practices can help businesses make better investment decisions that support operational objectives. So now is the requirement of more sophisticated people who are able to perform higher level tasks and can translate business needs into these new technologies.

Frequently Asked Questions

Why is supply chain transformation important?

Supply chain transformation is important because it can help organizations improve efficiency, enhance customer service, increase agility, mitigate risk, and drive innovation and growth.

What are some common challenges organizations face during supply chain transformation?

Some common challenges organizations face during supply chain transformation include resistance to change, lack of data visibility, outdated technology, talent shortages, and cost constraints.

What are some of the key technologies driving supply chain transformation?

Some key technologies driving supply chain transformation include the Internet of Things (IoT), blockchain, artificial intelligence (AI), machine learning (ML), and robotic process automation (RPA).

How can organizations ensure successful supply chain transformation?

Organizations can ensure successful supply chain transformation by developing a clear vision and strategy, engaging stakeholders, investing in the right technology and talent, collaborating with partners, and measuring and monitoring performance.

Key Takeaways

- For seamless operations, supply chain transformation calls for a comprehensive strategy that integrates people, processes, technology, and data.

- In order to minimise disruptions and guarantee company continuity, proactive risk management and resilience planning are crucial.

- Maintaining an advantage in the dynamic and always changing supply chain market requires constant innovation and agility.