Let our advance worrying become advance thinking and planning

Winston Churchill.

Automated Freight Management is consistently changing & progressing to reflect the needs of a progressively complex supply chain. Additionally, in the face of rising e-commerce activity, shippers are turning to advanced technology to guarantee reduced cost & an even customer experience. Also, automation permits freight managers to contemplate all aspects of the operation & avoid useless spending. Particularly, they amplify resource conservation. Moreover, it’s essential to understand how automation looks within the freight settlement side of the Supply Chain transformation.

In the current dynamic and cutthroat business environment, effective supply chain management is essential for businesses to satisfy client needs while keeping expenses under control. Effective goods management, which includes the organisation, carrying out, and overseeing of the transportation of goods from suppliers to customers, is a crucial component of a supply chain that is optimised. One effective way to help streamline these processes, increase visibility, and ultimately boost supply chain efficiency is through automated freight management. We shall examine how automated goods management is essential to the contemporary supply chain in this blog.

Need for Automated Freight Management

Effective supply chain management is essential for firms to remain competitive and satisfy customer needs in today’s fast-paced global economy. The control of logistics and goods is one of the most important elements of supply chain optimisation. Additionally, traditional approaches to goods management are frequently time-consuming, prone to inaccuracy, and may raise expenses. However, the introduction of automated goods management has completely changed how companies conduct their logistics, improving the supply chain’s efficiency and transparency. We’ll look at automated freight management’s role in supply chain optimisation in this blog.

It starts with the carrier sending an invoice & supporting documentation to an organization’s accounts payable department. Thus, traditional settlement systems would check manually- authorization of payment, the material, and innumerable minutes lost in adding payment data for processing.

But Automated freight settlement processes can devour the email, utilizing Robotics Process Automation (RPA). The system accordingly recognizes the carrier & matches the invoice to the quote within the TMS. It affirms the references & carrier documentation. Then, it alerts the team of missing data, if applicable. And it concludes payment account data, starting with the printing of physical checks. So, it reduces the manual work in the transfoamtion process.

Shippers who implement new technologies will be in a superior position to decrease freight costs.

Real-time Monitoring

Automated goods management systems enable organisations to track the status and location of their shipments by providing real-time visibility into the movement of items. This visibility enables proactive decision-making, allowing for the more efficient use of resources and the rerouting of shipments in the event of unforeseen delays. As a result, companies may lower the possibility of delayed deliveries and react swiftly to any disruptions, increasing client happiness and confidence.

From the time products leave the manufacturer until their final delivery, real-time monitoring provides a real-time picture of the whole supply chain. Companies can track shipments, watch their progress, and determine their precise location thanks to this visibility, which enhances control and coordination. Early problem identification, like as delays, route diversions, or unforeseen disruptions, is made possible by real-time monitoring. Supply chain managers can minimise the impact of these issues on operations by promptly responding to alerts from automated systems.

Cost-cutting

Traditional goods management frequently entails a lot of physical work, documentation, and communication with many stakeholders. These procedures are streamlined by automated technology, necessitating less human involvement. Automation lowers operational expenses, reduces errors, and improves data accuracy, which ultimately saves money for enterprises.

Making Decisions Based on Data

Automated goods management systems gather and examine a vast amount of data to offer insights into various supply chain components. Businesses can use this information to make informed decisions about carrier choice, demand forecasts, inventory management, and other issues. Companies can improve their supply chain strategy and more effectively respond to market dynamics by utilising data-driven decision-making.

Productivity and Efficiency

Systems for automating goods management contribute to increased supply chain productivity and efficiency. Thus, they simplify procedures including load planning, order management, and route optimisation. Also, with automation, firms may better utilise their resources, lessen the amount of physical labour required, and guarantee that shipments are handled as efficiently as possible.

Improved Client Service

A better customer experience is influenced by effective and trustworthy goods management. Moreover, automated systems can offer consumers precise delivery forecasts, real-time shipment tracking, and the option to reroute shipments as necessary. Customers are not only satisfied with this level of service, but it can also give businesses a competitive edge.

Security and Conformity

Automated goods management systems assist companies in adhering to a variety of rules, including safety laws and customs obligations. By offering features like tamper-evident tracking, they also increase the security of shipments by guaranteeing the integrity of items while in transit.

Sensitive data, including supplier contracts, customer information, and shipment details, is handled by automated goods management systems in large quantities. It is crucial to guarantee the security of this data. To safeguard data from cyber threats and unauthorised access, these systems employ access controls, secure user authentication, and encryption. Businesses must abide by data protection laws like the California Consumer Privacy Act (CCPA) and the General Data Protection Regulation (GDPR) while implementing automated systems. By helping to track and manage data in line with legal requirements, these technologies lower the chance of non-compliance.

Also read: Beyond the Horizon: Exploring the Future of Supply Chain

Sustainability

Automated goods management can also help create a supply chain that is more environmentally friendly. Thus, businesses can reduce their environmental impact by streamlining resource allocation, eliminating empty backhauls, and optimising routes. In consequence, this promotes corporate social responsibility objectives and lessens transportation’s total environmental impact.

Advanced algorithms are used by automated goods management systems to optimise routes, cutting down on wasted mileage and fuel use. Businesses can reduce their carbon footprints significantly by taking the most efficient routes. By effectively combining loads, these technologies guarantee that trucks are used to their maximum potential. A smaller carbon footprint and lower greenhouse gas emissions are the results of having fewer cars on the road. When possible, switching to more environmentally friendly modes of transportation, such intermodal or rail, is encouraged by the concept of sustainability in goods management. For a given shipment, automated algorithms are able to analyse and suggest the most environmentally friendly routes of transportation.

Scalability

The requirements for goods management alter as businesses expand. Also, automated systems can quickly adjust to changing requirements, enabling businesses to scale rapidly without suffering major operational disruptions. Businesses may need more complex goods management solutions as they expand and deal with higher demand. Automated systems are able to adjust to these changes with ease, guaranteeing that they can manage higher order complexity and higher shipment volumes.

Systems for scalable goods management provide supply chain visibility and control in real time. This guarantees that companies can effectively oversee and control the whole logistics process even as activities grow. Geographic expansion is made possible by automated technologies, which make it easier to organise and handle transportation across borders and even between different regions. They have no trouble managing operations across many locations and worldwide shipments.

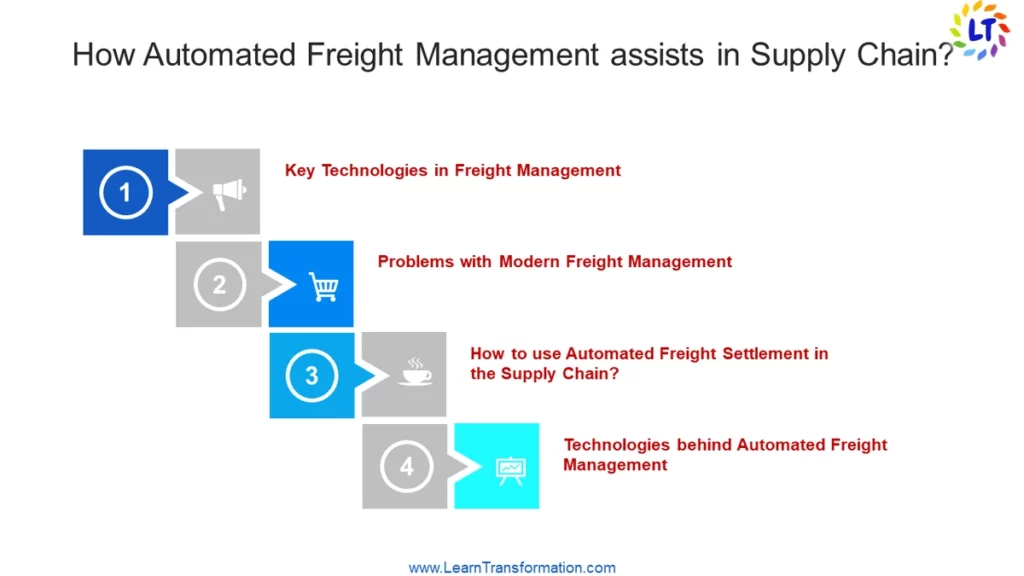

Technologies and services that will have a huge impact on shipping businesses including:

- Blockchain.

- Artificial intelligence and machine learning.

- Internet of Things.

- 3D printing.

- Autonomous mobile robots.

- Self-driving trucks.

- Shared truckload shipping.

Problems with Modern Freight Management

A supply-chain professional understands challenges for robotics and Automation in logistics will always exist and perceives that acknowledging the problems is necessary to find a solution. Additionally, a few of the top problems with modern freight management are:

- Poor use of robotics.

- Poor cybersecurity of systems.

- Failure to consider the whole picture.

- Incapacity to access elastic logistics.

- Dependency on out-of-date data exchange technologies.

- Inability to look beyond the now.

Leader’s Tip:

To reduce manual errors and save time, invest in reliable technology solutions that automate goods processes.

How to use Automated Freight Settlement in the Supply Chain?

Supply chain leaders realize a Transport Management System (TMS) is an indispensable tool in achieving efficiency of robotics in supply chain management. There are few tips to assist with automated freight settlement:

- Combine the TMS with the freight invoicing & payment platforms.

- Leverage analytics to differentiate freight quotes against submitted invoices.

- Recall, to sum up, the accessorial & their accuracy.

- Remove the manual work of tabulating & initiating payment processing.

- Track the system’s performance with KPIs that indicate invoices approved and those kicked back for errors or missing data.

- Keep informed of what carriers, anyhow of mode, are doing to require quick payment or digital invoicing.

Technologies behind Automated Freight Management

There are a lot of technologies that power automation in logistics and supply chain management & freight management. Additionally, these technologies permit companies to undergo their highs & lows by smoothing all the information they require to run their business & progressively transport their freight. Further, shippers need to know how these technologies make sense to a more profitable & productive supply chain.

1. Machine Learning & Big Data

Machine learning assists big data analytics in putting up to the success of Automated Freight Management using logistics automation software. Additionally, big data offers a complete picture of the status of the product. Moreover, as companies attain the ability to put in machine learning & big data to authorize real-time, automated exception management, all other estimates to decrease workload, amplify productivity & save money rise easier to realize.

2. Artificial Intelligence (AI) & Robotics Process Automation (RPA) Work in Sequence

These two advances to technology work in sequence to track sales, track all areas of transport, and above all, support the whole process for freight. Moreover, RPA and AI take the time to consume simple tasks and merge them into quick, easy-to-read reports & analytics for businesses.

3. Software-as-a-Service (SaaS)

SaaS is an elegant way of describing a platform like Amazon Prime, Netflix, and other subscription-based apps. Furthermore, the attraction of this type of service has resounded in recent years and has modified the supply chain industry in its ways. Additionally, the benefits of providing this type of service within the industry are having all data centralized & streamlining maintenance without inconvenience or complications.

Hand-picked for you: How is blockchain transforming business and money in 21st century?

Leader’s Tip:

Utilise real-time data analytics to increase visibility, decision-making, and overall supply chain performance.

Final Word

The sooner you implement new systems, the sooner you will reap the benefits. Shippers that accept cutting-edge tools & services will be in a better position to decrease costs, minimizing customer churn, identifying possible problems, and streamlining operations. Invest in leading technologies today, then watch your business get moving into the future with the help of automation of supply chain processes. Finally, automated goods management systems have emerged as a crucial tool for companies looking to optimise their supply chain processes. Thus, real-time visibility, cost savings, data-driven decision-making, increased productivity, improved customer service, compliance, security, and sustainability are all things they offer. For firms looking to maintain their competitiveness in a globalised market, investing in automated goods management becomes more than just a convenience as market demands change constantly.

FAQs

What is freight Management software?

Automated Freight Management is consistently changing & progressing to reflect the needs of a progressively complex supply chain. In the face of rising e-commerce activity, shippers are turning to advanced technology to guarantee reduced cost & an even customer experience. There are a lot of technologies that power automation in logistics and supply chain management & freight management like machine learning, big data, AI.

Why is freight management important?

The sooner you implement new systems, the sooner you will reap the benefits. Shippers that accept cutting-edge tools & services will be in a better position to decrease costs, minimizing customer churn, identifying possible problems, and streamlining operations. Invest in leading technologies today, then watch your business get moving into the future with the help of automation of supply chain processes.

Key Takeaways

- Automation in goods management increases efficiency, lowers costs, and lessens supply-chain delays.

- Streamlined procedures, like automatically generated load planning and routing, maximise resource usage and boost operational effectiveness.

- Greater visibility made possible by automated tracking and observation enables more effective inventory control and quicker order fulfilment.

Check out the Video: