Some people don’t like change, but you need to embrace change if the alternative is a disaster.

Elon Musk, Tesla Founder

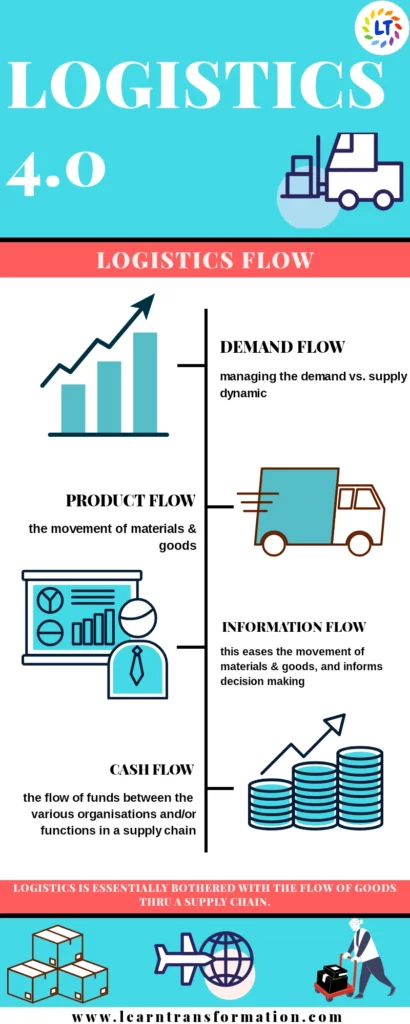

The networking and integration of logistical processes is known as logistics 4.0. In essence, Industry 4.0’s implications on logistics involve the networking and interlocking of customers, things, processes, and supply chain partners using information and communication technologies to boost a company’s efficiency and effectiveness. The supply chain is becoming more intelligent, networked, and technologically advanced as a result of Logistics 4.0. The interconnected pieces can operate independently thanks to its implementation.

These autonomous systems earn the designation of “smart” or “intelligent” because they interact, make decisions, share knowledge, and oversee logistics operations collaboratively. As a result, Logistics 4.0 primarily increases transparency, streamlines procedures, and reduces error rates.

- The next generation of supply chain management, known as logistics 4.0, makes use of cutting-edge technologies to increase productivity, visibility, and agility.

- To construct interconnected and intelligent logistics systems, it combines technologies including the Internet of Things (IoT), artificial intelligence (AI), robotics, and big data analytics.

- Real-time data from sensors, RFID tags, and linked devices makes it possible to track, monitor, and optimise products more effectively across the supply chain using Logistics 4.0.

- By assisting with demand forecasting, inventory management, and route optimisation, predictive analytics and AI algorithms help businesses save money and increase customer happiness.

- Autonomous vehicles and drones are used for last-mile delivery, enhancing speed and accuracy.

- Smart warehouses streamline inventory management, order fulfillment, and picking operations through automated technologies and robotics.

- Blockchain technology ensures safe and transparent transactions, as well as better traceability and supply chain visibility.

- Logistics 4.0 allows stakeholders to collaborate and share information in real time, enabling seamless coordination and decreasing delays.

- It converts the old supply chain into a customer-centric, responsive, and adaptive ecosystem capable of addressing changing market demands.

- Logistics 4.0 transforms the sector by increasing productivity, eliminating waste, and setting the way for future sustainable and efficient supply chains.

The logistics business is going through a significant upheaval in a time of accelerating technical breakthroughs and shifting consumer expectations. Logistics 4.0, frequently referred to as the smart supply chain of the future, represents a fundamental shift in how businesses manage their supply networks. This blog will explore the idea of Logistics 4.0, its essential elements, advantages, and potential effects on future international trade.

Leader’s Tip

Build a skilled workforce capable of managing and optimizing logistics 4.0 technologies.

A History of Logistics

It’s important to first examine the development of logistics in order to comprehend the significance of Logistics 4.0:

Logistics 1.0

When people started selling products in prehistoric civilizations, logistics really got started. With a heavy reliance on manual labour and simple tools, the main priorities were transportation and basic inventory management.

Logistics 2.0

Logistics developed into a more organised discipline with the industrial revolution. Although assembly lines and railroads increased efficiency and scale, physical labour remained a significant part of logistical operations.

Logistics 3.0

The logistics industry was computerised in the latter half of the 20th century. Computers were first used by businesses for cargo tracking, route optimisation, and inventory control. During this period, developers created the first Transportation Management Systems (TMS) and Warehouse Management Systems (WMS).

Also read: Best Supply Chain Management Interview with Mohammad Iqbal – The Best Ever in Supply Chain Domain

Supply Chain Intelligence in Logistics 4.0

The fourth industrial revolution, known as logistics 4.0, is fueled by connectivity, automation, and digital technologies. The ecosystem of the supply chain is smooth and sophisticated thanks to its adoption of the Internet of Things (IoT), artificial intelligence (AI), big data analytics, blockchain, and cloud computing.

Key Components of Logistics 4.0

Logistics 4.0 is an extremely sophisticated and integrated method of managing the supply chain that makes use of digital technology to improve productivity, visibility, and overall performance. The main elements of Logistics 4.0 are as follows:

- The Internet of Things (IoT): stands for IoT, and IoT sensors and devices integrate into various assets, including products, containers, and cars. These sensors gather current information on variables such as location, temperature, humidity, and others. Through the supply chain, this data enables tracking and offers visibility.

- Artificial intelligence (AI) and machine learning: To provide useful insights, AI and machine learning algorithms examine enormous datasets. These technologies enable predictive analytics for proactive problem solving, route optimization, and demand forecasting. Thus, virtual assistants and chatbots powered by AI can improve customer support and service.

- IoT sensors, transaction records, and other sources produce enormous volumes of data, which big data analytics analyses. Furthermore, it offers a deeper comprehension of supply chain operations, assisting businesses in making data-driven choices and streamlining procedures.

- Blockchain technology: Blockchain guarantees the security and openness of supply chain transactions. Thus, by recording each stage of a product’s journey in an immutable ledger, it improves supply chain integrity, authenticity verification, and traceability.

- Cloud computing: Cloud-based platforms offer centralized hubs for data processing, storage, and collaboration. They make information accessible in real-time, make it easier for supply chain partners to share data, and lessen the requirement for on-premises IT equipment.

- Robotics and automation: Automation technologies, such as self-driving cars, drones, and warehouse robots, perform last-mile deliveries, order picking, inventory management, and other tasks. These innovations increase productivity, lower labour expenses, and cut back on mistakes.

- Advanced Analytics and Visualisation Tools: Dashboards and data visualisation tools make complex data easier to access and comprehend. They give supply chain professionals the ability to keep an eye on operations, analyse key performance indicators (KPIs), and make decisions quickly.

- IoT sensors and AI algorithms collaborate to forecast when equipment and assets need repair or replacement through predictive maintenance. Additionally, this lowers downtime, increases asset lifespans, and guarantees continuous supply chain operations.

- Strong cybersecurity measures are necessary to safeguard sensitive data from online threats and unauthorised access as supply chains grow more digitalized and networked.

- Companies use virtual and augmented reality (AR and VR) technologies for training, remote assistance, and visualizing supply chain processes. Thus, they support maintenance and troubleshooting operations and increase worker productivity.

- 3D printing (additive manufacturing) makes decentralized production possible, eliminating the need for conventional manufacturing and transportation. Hence, it makes it possible to produce customised items and spare parts on demand, which reduces inventory and speeds up response times.

Together, these crucial Logistics 4.0 elements build a supply chain ecosystem that is smarter, more effective, and more responsive. Thus, organisations can employ these technologies to gain a competitive advantage, lower expenses, improve customer experiences, and encourage sustainability in their supply chain operations.

Leader’s Tip

Ensure data accuracy, quality, and consistency across your supply chain.

Benefits of Logistics 4.0

Logistics 4.0, which integrates digital technology, automation, and connectivity in supply chain management, provides businesses and the sector as a whole with a number of advantages. These advantages consist of:

- Efficiency Gains: Automation and data-driven decision-making streamline logistical processes, saving time and money on jobs like route planning, inventory control, and order processing.

- Cost reduction: Logistics 4.0 lowers labour costs, fuel costs, and total operating costs by simplifying processes and minimising manual interventions.

- Enhanced Visibility: End-to-end supply chain visibility is provided via real-time tracking and data analytics. Furthermore, due to the ability to track shipments and inventories, businesses are better able to make educated decisions and provide better customer service.

- Faster delivery times, accurate order fulfilment, and real-time tracking options all contribute to an improved customer experience. Hence, customers may place purchases more easily and with fewer mistakes or delays.

- Optimised goods Management: Cutting-edge analytics and predictive algorithms assist businesses in keeping the right amount of goods on hand. As a result, carrying costs are decreased, cash flow is improved, and overstocking and stockouts are avoided.

- Sustainability: Through better inventory management, logistics 4.0 technologies optimise routes, cut down on fuel use, and minimise waste. Thus, this supports supply chain practises that are more sustainable and beneficial to the environment.

- Risk reduction: Predictive analytics and real-time data can detect possible dangers in the supply chain, enabling businesses to take proactive steps to reduce these risks. Thus, this includes delays brought due by inclement weather, problems with suppliers, or traffic jams.

Also read: Logistics Literature: Best Supply Chain Books to Inspire

In conclusion, Logistics 4.0 offers a wide range of advantages, including cost savings and increased effectiveness as well as improved client experiences and sustainability. These advantages will be more and more crucial for maintaining competitiveness in a business environment that is continually changing as the logistics sector continues to embrace digital transformation.

Future Consequences

Logistics 4.0 is not just a pipe fantasy of the future. Additionally, ffering services that are quicker, more dependable, and more affordable gives businesses using these technologies a competitive advantage. But it also presents difficulties, like the need for a qualified labour and cybersecurity issues.

- Employment Transformation

To manage and optimise these cutting-edge technology, the logistics sector will need a staff with expertise in data analytics, artificial intelligence, and robots. To meet these expectations, reskilling and upskilling will be necessary.

- Cybersecurity

The risk of cyberattacks rises as supply chains become more integrated and dependent on digital technologies. Thus, strong cybersecurity measures will be required by businesses to safeguard sensitive information and avoid interruptions.

- Regulations and Ethical Issues

Regulators will need to change to ensure privacy and moral use of data in supply chain operations as a result of greater data gathering and automation.

- Chain of Supply Resilience

While improving efficiency, Logistics 4.0 also highlights the significance of supply chain resilience. To adapt to unanticipated disturbances, businesses should design their systems with redundancy and flexibility.

5 Best Logistics 4.0 Books

Global Reader’s Click Below:

- Supply Chain Management For Dummies

- Supply Chain Logistics Management

- Supply Chain Management: A Logistics Perspective

- Value Stream Mapping: How to Visualize Work and Align Leadership for Organizational Transformation Hardcover

- The Toyota Way: 14 Management Principles from the World’s Greatest Manufacturer

India Reader’s Click below:

- Logistics and Supply Chain Management

- Supply Chain & Logistics Management-KL

- Operations, Logistics and Supply Chain Management (Lecture Notes in Logistics)

- Lean In: Women, Work, and the Will to Lead

- The Lean Product Playbook: How to Innovate with Minimum Viable Products and Rapid Customer Feedback

Conclusion

The future of supply chain management is represented by logistics 4.0, which is characterised by connectivity, automation, and intelligence. It offers improved client experiences, greater efficiency, and a more environmentally friendly approach to logistics. But it also necessitates a proactive strategy for cybersecurity, workforce development, and ethical issues. The logistics sector is primed for a transition that will reshape international trade as we currently understand it as we continue to embrace this digital revolution. Those who can adapt will prosper in the futuristic smart supply chain.

Key Takeaways

- Logistics 4.0 transforms supply chain with IoT, AI, blockchain, analytics.

- Logistics 4.0: Data-driven decisions optimize inventory, routes, and operations.

- AI, machine learning predict demand, optimize routes, prevent operational disruptions.

FAQs

What is logistics 4.0 & how does it affect supply chain management?

The logistics business is going through a significant upheaval in a time of accelerating technical breakthroughs and shifting consumer expectations. A fundamental shift in how businesses manage their supply networks is represented by logistics 4.0, which is frequently referred to as the smart supply chain of the future

What new technologies are affecting supply chains under Industry 4.0?

IoT sensors and AI algorithms collaborate to forecast when equipment and assets need repair or replacement through predictive maintenance. This lowers downtime, increases asset lifespans, and guarantees continuous supply chain operations.

Strong cybersecurity measures are necessary to safeguard sensitive data from online threats and unauthorised access as supply chains grow more digitalized and networked.

Virtual and augmented reality (AR and VR) technologies are used for training, remote help, and supply chain process visualisation. They support maintenance and troubleshooting operations and increase worker productivity

Also check out: