A leader is best when people barely know he exists, when his work is done, his aim fulfilled, they will say: we did it ourselves.

Lao Tzu

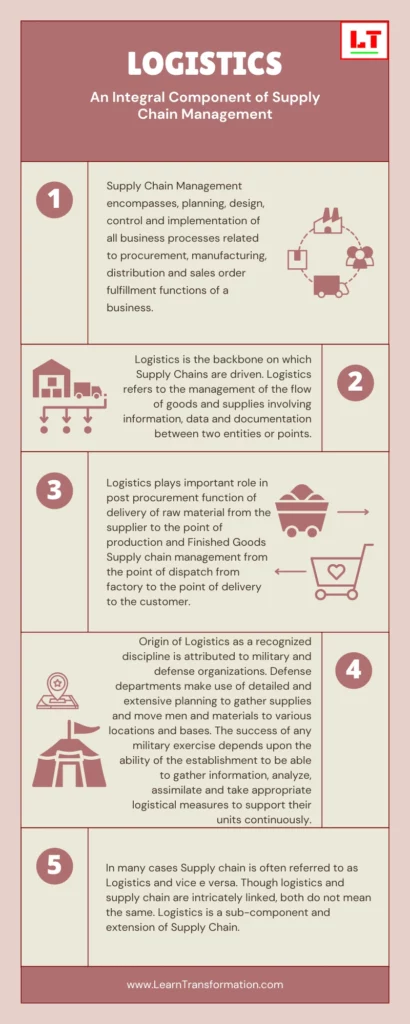

A crucial part of supply chain management is logistics. From the point of origin to the point of consumption, it involves the planning, execution, and administration of commodities, services, and information. To move raw materials and finished items from and to all remote places across the world, all these activities entail different networks of vendors and service providers that are integrated and coordinated by the organization’s supply chain experts.

As an essential component of supply chain management, logistics plays a critical role. Here are some crucial aspects that emphasise its significance:

- Goods Movement: Logistics ensures goods move effectively and timely from suppliers to customers, ensuring availability at the right place and time.

- Warehousing and Inventory Management: Logistics includes warehousing, inventory management, and distribution, as well as ensuring proper stock levels, minimising stockouts, and optimising storage space.

- Transportation Management: Transportation management entails managing transportation networks, selecting appropriate modes of transportation (e.g., road, rail, air, sea), and optimising routes to save costs and delivery times.

- Order Fulfilment: To satisfy client needs properly and on schedule, logistics enables smooth order processing and fulfilment, including order picking, packing, and shipment.

- Supply Chain Coordination: Logistics supports coordination and collaboration among multiple supply chain participants, including suppliers, manufacturers, distributors, and retailers, to ensure a continuous flow of goods and information.

- Cost Optimization: Effective logistics reduces transportation and inventory costs, enhancing supply chain efficiency for cost optimization.

- Customer Satisfaction: Logistics directly affects customer satisfaction by ensuring timely delivery, accurate order fulfillment, and efficient handling of inquiries or complaints.

- Risk Management: Logistics employs risk management strategies like contingency planning, supply chain visibility, and disaster recovery to ensure business continuity and prevent disruptions.

- Sustainability and Environmental Impact: Logistics plays a role in minimising the environmental impact of supply chain operations by optimising transportation routes, lowering emissions, and introducing eco-friendly practises.

In conclusion, logistics is an important component of supply chain management, encompassing activities such as transportation, warehousing, inventory management, order fulfilment, and coordination, all of which contribute to cost optimisation, customer satisfaction, and overall supply chain performance.

Effective commodity transportation is vital for modern commerce in a fast-paced, interconnected world. This blog explores logistics’ vital role in supply chain management and its role in guiding commodity movement from origin to destination.

The significance of logistics cannot be emphasised as the world’s markets grow and consumer expectations rise to previously unheard-of levels. It serves as the foundation for ensuring punctual, quantity-appropriate, and flawless delivery of goods while cutting costs and mitigating environmental impact. In this exploration of logistics, we will delve into its intricacies and the pivotal role it plays in shaping global business success and customer satisfaction. Logistics is the engine that drives the wheels of commerce ahead, from inventory management to technological developments and sustainability.

Leader’s Tip

Use demand forecasting and data analytics to refine inventory decisions.

What is Logistics?

Logistics involves planning, executing, and managing the efficient flow of goods, services, information, and resources from origin to destination. Logistics covers shipping, warehousing, inventory control, order fulfillment, and stakeholder coordination to ensure timely, intact delivery to the correct place. In order to meet client needs, control costs, and streamline operations, firms must effectively manage their supply chains.

The Backbone of Supply Chain

Because it acts as the key support mechanism for ensuring the efficient and seamless flow of goods, information, and resources throughout the whole supply chain network, logistics is frequently referred to as the “backbone” of the supply chain. Thus, supply chain operations would be disorganised, ineffective, and unable to satisfy customer demands without good logistics.

Transportation, inventory management, warehousing, order processing, and distribution are just a few of the tasks that are included in logistics. In the end, it links suppliers to customers by ensuring that goods are sourced, produced, stored, and delivered in a timely way.

Essentially, logistics serves as the spine of the supply chain, enabling companies to meet customer expectations, save costs, and react quickly to shifting market conditions. It is a vital part of contemporary commerce since it is crucial to establishing supply chain effectiveness and efficiency.

Also read: Into the Future: Logistics 4.0 and the Evolution of Supply Chains

Inventory Management

Logistics and supply chain management are closely related, and inventory management is a crucial part of both. It entails organising, tracking, and managing a company’s inventory levels to guarantee that goods are accessible when required while minimising surplus stocks and related expenses. Here are some justifications for why inventory control is crucial in the context of logistics and supply chain management:

- Inventory management assists companies in maintaining the delicate balance between supply and demand. It avoids stockouts and delays in order fulfilment by making sure that products are available when customers need them.

- lowering holding costs: storing, insuring, and obsolescence charges are associated with excess inventory. Furthermore, by maintaining optimal inventory levels, effective inventory management reduces these holding costs.

- Improving client Satisfaction: Inventory management makes sure that goods are available right away to satisfy client expectations. As a result, customer satisfaction increases because orders are processed quickly and accurately.

- Production optimisation: It enables businesses to match their production plans with actual demand. This decreases overproduction, which can lead to surplus inventory.

- Supply Chain Efficiency: By avoiding bottlenecks and maintaining a seamless flow of goods from suppliers to customers, effective inventory management helps to improve supply chain efficiency overall.

- Cost Management: It aids in the management of expenses related to ordering, carrying, and storing inventory. Businesses can make better use of their financial resources by reducing surplus inventory.

- Inventory data can be used for demand forecasting, allowing companies to plan their purchases and output more effectively.

- Risk Reduction: Properly managing inventory can reduce risks related to supply chain disruptions, such as unanticipated demand increases or supplier delays.

- Many businesses use lean inventory management techniques, which minimise surplus inventory in an effort to cut waste and increase productivity.

- Advanced inventory management systems leverage data analytics to provide insights into the performance of the inventory, assisting businesses in making data-driven decisions.

In conclusion, logistics’ inventory control is the key to ensuring that goods are available when needed, reducing costs, and boosting the supply chain’s overall effectiveness. Thus, it has a significant impact on customer happiness, financial success, and operational excellence and is an essential component of supply chain and logistics strategy.

Leader’s Tip

Invest in technology and systems that provide real-time visibility into your logistics processes.

Cost Efficiency

Cost effectiveness is an essential and fundamental element of supply chain management, and it is crucial to logistics. To be competitive and profitable, firms must achieve cost efficiency in logistics. Cost effectiveness is essential in the context of logistics and supply chain management for the following reasons:

- Minimising Operating Costs: Logistics operations cover a wide range of tasks, including order processing, inventory management, transportation, and warehousing. Thus, they are implementing initiatives to reduce operating costs, including fuel, labor, storage, and other expenses, in these areas.

- Transportation Cost Optimisation: A company’s logistics costs may include a sizable share of transportation expenditures. Cost-effective logistics methods optimise modes, carriers, and routes of transportation to lower freight costs while assuring on-time delivery.

- Inventory holding expenses include higher storage costs, a larger risk of obsolescence, and capital encumbrance. In order to reduce holding costs, cost-effective inventory management emphasises maintaining ideal inventory levels.

- Costs Associated with Order Fulfilment: Processing and fulfilling client orders efficiently reduce costs in picking, packaging, and shipping customer orders. Automation and streamlined processes may achieve cost savings in this area.

- Collaboration with suppliers: Working together with suppliers can result in cost savings. Just-in-time (JIT) inventory practises, as an illustration, cut down on the need for extra inventory and related carrying expenses.

- Modern logistics must make decisions that are data-driven in order to be effective. Moreover, data-driven insights can uncover cost reduction opportunities, including inventory optimization, demand forecasting, and route optimization.

- Technology Integration: Technological solutions like Transportation Management Systems (TMS) and Warehouse Management Systems (WMS) enhance visibility, control, and cost efficiency.

- Sustainability: Sustainable logistics strategies not only support environmental objectives but also lower costs. Long-term cost savings are possible with, for instance, environmentally friendly packaging and fuel-efficient transportation methods.

- Fostering a culture of continuous improvement in logistics and supply chain management inspires teams to consistently implement cost-saving measures.

- Competitive Advantage: Organisations with cost-effective logistics can provide competitive pricing to clients, giving them a possible market advantage.

Also read: Logistics Literature: Best Supply Chain Books to Inspire

In conclusion, cost-effective logistics is vital for supply chain management, influencing organizational viability and competitiveness. Companies can lower costs, increase profitability, and improve supply chain performance by optimising a variety of logistical processes.

Global Reach

In supply chain management and logistics, having a global reach is an essential and necessary component. Thus, in today’s interconnected world, where firms operate globally for multiple reasons, expanding the supply chain globally becomes crucial:

- Global logistics give companies access to new markets and customers all around the world. This broader audience may present prospects for corporate growth and expansion.

- Diverse Sourcing: Businesses can source products and materials globally, reducing risk and diversifying their supply base.

- Efficient Distribution: Effective global logistics networks enable quick, cost-efficient product distribution to foreign clients, boosting customer satisfaction.

- Customization:Global businesses can tailor goods and services to diverse market and clientele needs.

- Economies of Scale: Global expansion yields economies of scale, reducing per-unit production and shipping costs, enhancing cost-effectiveness.

- Operating across several regions helps reduce the risks brought on by supply chain disruptions in a single location. Additionally, depending on the situation, businesses can relocate manufacturing or sourcing.

- Global Sourcing and Procurement: Global logistics facilitate cost-effective sourcing and purchasing of goods from international suppliers, maximizing quality.

- Compliance with Regulatory Requirements: Global logistics experts navigate complex international regulations to ensure import/export compliance across various nations and regions.

- Cultural Sensitivity: Successful global logistics depends on an understanding of cultural nuances and market dynamics. It is crucial to adjust logistics plans to accommodate regional preferences and customs.

- Competitive Advantage: Organizations with a robust global logistics presence outperform rivals with extended reach and faster deliveries.

- A globally diverse supplier chain improves supplier chain resilience. When a corporation operates in numerous nations, disruptions in one area may not have as much of an impact.

In conclusion, organisations that want to expand, be resilient, and be competitive globally must have a worldwide reach in logistics. Managing complex global logistics networks, following rules, and understanding various market demands is necessary .Companies can seize opportunities, manage risks, and enhance efficiency by extending their supply chain reach effectively.

4 Best Supply Chain Management Books

Global Reader’s Click Below:

- The Obstacle Is the Way: The Timeless Art of Turning Trials into Triumph

- Essentials of Supply Chain Management (Essentials Series)

- Operations and Supply Chain Management

- Dare to Lead: Brave Work. Tough Conversations. Whole Hearts.

India Reader’s Click below:

- Supply Chain Management | By Pearson

- Supply Chain Management 2/e: Text and Cases

- Essentials of Supply Chain Management (Essentials Series)

- Supply Chain Logistics Management | 4th Edition

Conclusion

The logistics lynchpin ensures that goods move through the complex web of the contemporary supply chain. Its importance to consumer happiness, cost effectiveness, worldwide reach, and inventory management cannot be emphasised. Thus, logistics remains at the forefront, orchestrating supply chain management and driving commerce as firms adapt to changing expectations and markets. In a world valuing speed and precision, logistics undoubtedly drives supply chain success as the locomotive.

Key takeaways

- Since logistics links different supply chain operations and stakeholders, it is frequently referred to as the supply chain’s “backbone.”

- In order to increase profitability, logistics plays a crucial role in cost management by optimising warehousing, transportation, and operational costs.

- A company’s access to various sourcing, distribution, and customer bases is facilitated by global logistics, which increases its market reach to foreign markets.

FAQs

How logistics is a component of the supply chain?

The significance of logistics cannot be emphasised as the world’s markets grow and consumer expectations rise to previously unheard-of levels. It acts as the cornerstone for ensuring timely, quantity-appropriate, and pristine delivery of goods, while minimizing costs and environmental impact.

What is the integral part of the supply chain?

Logistics is often termed the “backbone” of the supply chain because it supports the efficient flow of goods, information, and resources. Supply chain operations would be disorganised, ineffective, and unable to satisfy customer demands without good logistics.

Also check out: