Good is the enemy of great. That’s why so few things become great.

James C. Collins

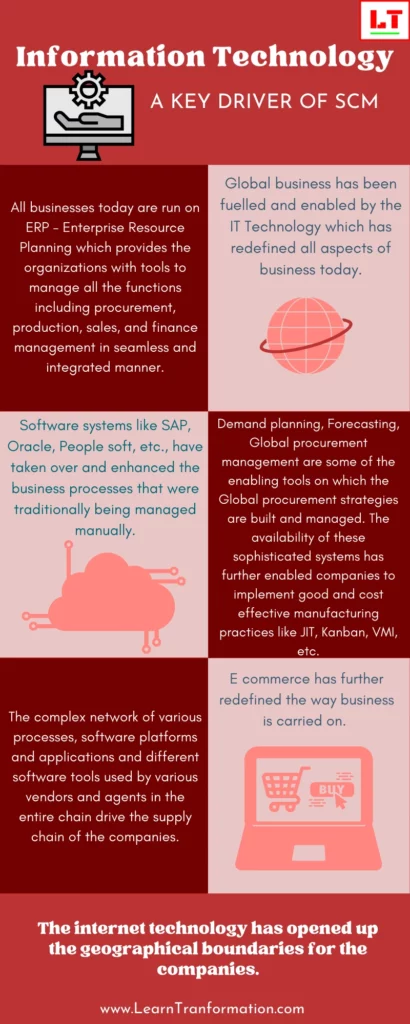

The business of matching demand with supply is continually changing and evolving in a globalized business environment marked by geographically dispersed markets, global raw material procurement sources, and cheaper manufacturing and labor markets available in developing nations. The success of supply chain management (SCM) can make or destroy a corporation in the competitive, global marketplace of today. Information technology (IT) has become a key driver of SCM’s increased effectiveness and efficiency. The crucial role of IT in supply chain management (SCM) is explored in this blog, opening doors for improved operations, data-driven decision-making, and unmatched customer happiness.

- Connectivity: Information technology facilitates real-time data exchange and cooperation by enabling seamless connectivity and communication across the whole supply chain.

- Data-driven Decision Making: IT systems capture, store, and analyse massive volumes of supply chain data, enabling businesses to make informed, data-driven decisions.

- Automation and efficiency: From inventory management and order processing to transportation and warehousing, IT systems automate manual procedures, streamlining supply chain operations and enhancing efficiency.

- Supply Chain Visibility: IT systems enable real-time visibility into the movement of commodities, inventory levels, and demand patterns, allowing for proactive planning and risk management.

- Integration and cooperation: IT facilitates integration and cooperation across supply chain stakeholders, enabling stronger relationships, information exchange, and coordination for improved overall performance.

- Improved Customer Experience: IT supports improved customer experience with capabilities such as online buying, shipment tracking, and personalised communication.

- Advanced Analytics and Forecasting: IT provides advanced analytics and forecasting models by leveraging historical data and prediction algorithms to optimise inventory levels, demand planning, and resource allocation.

- Traceability and Compliance: IT solutions enable traceability and ensure compliance with regulations and standards, allowing organisations to track and document product movement and quality across the supply chain.

- Agility and Adaptability: IT systems give the flexibility and agility required to adapt swiftly to market changes, interruptions, and client demands.

- Continuous Improvement: IT aids continuous improvement programmes by providing performance measurements, feedback loops, and the capacity to identify opportunities for optimisation and process advancement.

Let’s See The Role of IT in Supply chain management (SCM)

1. It helps in Gaining Real-time Visibility and Tracking.

Gaining real-time visibility and tracking capabilities has changed the game in the area of supply chain management (SCM). IT has revolutionized SCM, enabling companies to monitor, manage, and optimize supply chains in previously unthinkable ways. This blog explores real-time visibility and tracking’s critical role in SCM and how IT is transforming the flow from producer to consumer.

- IoT-enhanced visibility:Information technology, especially the Internet of Things (IoT), has introduced an unprecedented era of visibility. SCM experts can monitor asset location, health, and performance in real-time, thanks to IoT sensors on commodities, vehicles, and infrastructure.

- Optimised Inventory Management: A crucial component of effective SCM is the real-time monitoring of inventory levels. IT-driven solutions enable companies to maintain optimal stock levels, reduce excess inventory, and eliminate stockouts. This reduces expenses while also raising client happiness.

- Precision in Transportation: The accurate tracking of cargo and vehicles is made possible by GPS technology and route optimisation software. Tracking delivery progress, adjusting routes for traffic or weather, and ensuring on-time deliveries are all achievable with IT-driven solutions. The total supply chain’s reliability is improved by this level of management.

- Demand Sensing and Forecasting: Businesses can detect changes in demand patterns as they occur thanks to real-time data collecting and analytics. By analyzing data, companies adapt production, replenish inventory, and adjust supply chain strategies in response to changing client demands.

- Managing Risk Proactive risk management is made possible by real-time visibility. Businesses can foresee disruptions, such as weather delays or geopolitical events, and prepare to minimize their impact on the supply chain.

- Supply chain specialists can make dynamic judgements since they have access to real-time data. They can, for instance, reroute goods to avoid traffic jams, manage resources effectively, and react quickly to unforeseen difficulties.

- Customer Transparency: Real-time tracking is a valuable tool for customer support as well as an internal tool. Businesses enhance customer trust and experience with accurate real-time order updates.

Supply Chain Management now has the benefit of real-time tracking and visibility because to information technology. Due to this capabilities, SCM is now a flexible, adaptable, and customer-focused discipline. IT-driven real-time visibility guides supply chains to greater efficiency, lower costs, and improved customer satisfaction in an agile, precise era. In today’s competitive SCM landscape, adopting this technology is not just a choice but a strategic necessity.

Leader’s Tip

Choose IT systems and software that align with your specific SCM needs.

2. IT helps in Data Analytics and Predictive Insights.

An important transition has occurred in the dynamic field of supply chain management (SCM) as a result of the integration of IT. The power of data analytics and predictive insights is one of IT’s most important contributions to SCM. This blog examines how IT-enabled data-driven decision-making is transforming the SCM environment and giving businesses a competitive edge by enabling them to make better, more informed decisions.

- The SCM Revolution Driven by Big Data: Information Technology has made it possible to gather and analyse enormous volumes of data from numerous supply chain touchpoints. Big Data analytics sorts through this mass of data to find previously unnoticed patterns, trends, and connections. The basis for more intelligent decision-making is this data-driven methodology.

- Precision in Demand Forecasting: Data analytics enables businesses to go beyond conventional forecasting techniques. Businesses can create extremely precise demand projections by looking at past data, market patterns, and even external elements like weather or economic indicators. They can predict consumer demands thanks to predictive insights, and they can then modify their production and inventories to meet those needs.

- Inventory optimisation: Businesses can optimise their inventory management by utilising data analytics. Instead of depending on fixed safety stock levels, they use dynamic models that change in response to changes in the demand in real time. With this optimisation, carrying expenses are kept to a minimum and constant product availability is guaranteed.

- Data analytics helps to assess the performance of suppliers, enhancing supplier relationships. Companies can pinpoint areas for improvement, bargain for better terms, and strengthen collaboration by analysing supplier data. As a result, supply chain risks are decreased and procurement procedures become more effective.

- Planning scenarios and risk mitigation: Businesses may anticipate future interruptions, such as natural disasters and geopolitical events, thanks to predictive insights. With this information, they may create backup plans and simulations of potential events to reduce risks and preserve supply chain continuity.

- Improved client Experience: Data analytics powered by IT provide for a deeper comprehension of client behaviour. Companies can offer personalised experiences, segment their consumer base, and customise marketing techniques. This increases consumer loyalty in addition to boosting sales.

- Operational Efficiency and Cost Reduction: Data analytics-based smarter decision-making results in more efficient operations. Businesses may pinpoint inefficiencies in their supply chain operations, improve the flow of traffic, and cut waste. In the end, this results in reduced costs and increased profitability.

- Real-time Decision-Making: Businesses can take quick judgements thanks to real-time data analytics. SCM experts can react quickly to changing conditions by altering production schedules, rerouting shipments, or reallocating resources.

A new era of more intelligent, agile, and pro-active decision-making has begun as a result of information technology’s integration of data analytics and predictive insights into supply chain management. These qualities are priceless in a global market characterised by ambiguity and rapid change. Companies using IT-driven data analytics can optimize supply chains and gain a competitive edge by precisely exceeding customer expectations. Adopting data-driven insights isn’t just a choice in the developing SCM market; it’s a strategic need for long-term success.

Also read: 31 Supply Chain Quotes by Great Leaders

3. It helps in Inventory Optimization.

Information Technology (IT) is at the centre of the digital revolution that Supply Chain Management (SCM) is undergoing. Inventory optimisation is one of IT’s numerous contributions to SCM that truly changed the game. This blog explores how IT-driven inventory solutions help organizations streamline processes, sharpen their competitive edge, and manage inventory effectively.

- Information technology gives organisations the capacity to gather, process, and analyse enormous amounts of data pertaining to their inventory. Data-Driven Inventory Insights. This data-driven strategy offers priceless insights into supply and demand dynamics and consumption trends.

- Dynamic Demand Forecasting: Businesses can go beyond static projections by using IT-driven tools and algorithms. They are able to produce extremely precise demand estimates by combining historical data, market patterns, and current information. Due to the ability to make real-time inventory adjustments, organisations can lessen surplus inventory and prevent shortages.

- JIT (Just-in-Time) Inventory: JIT inventory management, refilling inventory when needed, reduces costs associated with large inventory quantities. JIT optimises working capital while minimising storage expenses and waste.

- Collaboration with suppliers: IT platforms make it easier to collaborate and communicate with vendors.

Sharing real-time inventory data with suppliers improves collaboration, reduces lead times, and enhances overall supply chain effectiveness for businesses. - Automated Replenishment: When inventory levels reach predetermined thresholds, IT-driven solutions can automate the reordering process. This reduction in the danger of stockouts not only buys time but also ensures swift stock replacement.

- Multi-Location Inventory Management: IT systems offer visibility across all sites for companies with various storage facilities. With this centralized view, which requires less need for safety stock and improves stock allocation, we maximize overall inventory.

- Reduction in Holding Costs: Businesses can drastically cut holding costs, such as storage, insurance, and depreciation charges, by optimising their inventory levels. The outcome is an increase in profitability.

- Improved Customer Satisfaction: Inventory optimization guarantees product availability for customers when they need it. This raises revenue and brand recognition in addition to increasing consumer pleasure.

- Risk reduction: IT-driven inventory management is capable of identifying and reducing risks like supply chain interruptions or unexpected shifts in demand. Companies can create backup plans to lessen the effects of unexpected disasters.

Leader’s Tip

Foster strong relationships with IT solution providers and vendors to ensure timely support and updates when needed.

4. It helps in Efficient Order Processing and Fulfillment

IT has brought efficiency and accuracy to SCM, especially in order processing and fulfillment. This blog explores how IT-driven solutions revolutionize SCM by speeding lead times, enhancing order processing, and boosting customer satisfaction.

- Automated Order Capture: Thanks to information technology, organisations may streamline the order capture procedure. IT ensures quick and accurate order recording, reducing errors via online ordering and electronic data exchange (EDI) systems.

- Order tracking in real-time is made possible by IT, giving users access to order status in real-time. Customers and stakeholders can follow their orders all the way from placement to delivery, promoting openness, confidence, and proactive problem-solving.

- Inventory visibility: Businesses can get a complete picture of their inventory thanks to platforms powered by IT. This visibility ensures efficient order allocation and shorter lead times by sourcing products from the nearest, ideal location.

- Dynamic order routing uses IT algorithms to analyse a variety of variables, including product availability, shipping possibilities, and delivery promises. As a result, delivery routes are improved, transportation expenses are decreased, and orders are filled more quickly.

- IT seamlessly incorporates data from demand forecasting into order processing. Businesses may anticipate client expectations when combined with predictive analytics, avoiding stockouts and lowering surplus inventory.

- Automated Communication: Systems powered by IT streamline communication amongst supply chain stakeholders. Automation cuts delays and boosts efficiency, notifying customers of order status and alerting warehouse personnel for picking and packing.

- Improved Customer Experience: More efficient order processing and correct fulfilment result in happier customers. Customers who are satisfied are more inclined to shop there again and recommend the brand, which improves a business’s standing and bottom line.

- Reduced Lead Times: IT-driven order processing reduces delays from order receipt to delivery at every level. Products reach customers more quickly because to shorter lead times, which helps businesses stay competitive.

- Data-Driven Decision-Making: IT gives useful information on the effectiveness of order processing, enabling firms to spot bottlenecks and areas for development. This data-driven methodology guarantees ongoing improvement of order processing tactics.

- IT-driven systems can be customised to fit a variety of business requirements. Moreover, IT systems can be easily modified to implement rule-based order processing, third-party logistics integration, or workflow configuration.

Also read: Supply Chain Elements-Best 6 Elements

Within Supply Chain Management, information technology has become a potent force for improving order processing and fulfilment. Thus, businesses using IT-driven solutions enhance customer satisfaction, reduce lead times, and streamline processes for a competitive edge. In the ever-changing SCM industry, IT-driven efficiency is vital, not just a benefit, with speed and precision as priorities.

4 Best Information Technology Books

Global Reader’s Click Below:

- Start a Successful Career Today in Information Technology: Computer Science + Computer Engineering

- The New Normal in IT: How the Global Pandemic Changed Information Technology Forever (Wiley CIO)

- Rethinking Information Technology Asset Management

- Information Technology Essentials: Basic Foundations for Information Technology Professionals

India Reader’s Click below:

- Fundamentals Of Information Technology

- Information Technology: Inside And Outside

- The Supply Chain Revolution: Innovative Sourcing and Logistics for a Fiercely Competitive World

- Managing Supply Chain Operations

Conclusion

Information technology serves as a driving force behind efficiency, accuracy, and competitiveness in the always changing world of supply chain management. IT will continue to influence the future of SCM as companies rely more and more on digital solutions, providing creative ways to satisfy customer demands while streamlining processes and lowering costs. In today’s dynamic and demanding global market, adopting IT as a primary SCM driver is not just an option but a requirement.

Key takeaways

- Information technology streamlines and eliminates manual errors in key SCM operations like order processing, inventory control, and logistics.

- IT offers real-time visibility into supply chain operations, empowering stakeholders to follow orders, keep an eye on inventory, and act quickly on data.

- Businesses may anticipate client wants, avoid stockouts, and maximise inventory levels by integrating demand forecasting data.

FAQs

What is the role of information technology in SCM?

Information technology (IT) has become a key driver of SCM’s increased effectiveness and efficiency. The crucial role that IT plays in SCM is explored in this blog, opening doors for improved operations, data-driven decision-making, and unmatched customer happiness.

How does information technology affect supply chain management SCM?

Information technology serves as a driving force behind efficiency, accuracy, and competitiveness in the always changing world of supply chain management. IT will continue to influence the future of SCM as companies rely more and more on digital solutions, providing creative ways to satisfy customer demands while streamlining processes and lowering costs. In today’s dynamic and demanding global market, adopting IT as a primary SCM driver is not just an option but a requirement.

Also check out: