‘ It is not the Organizations that are competing, it’s a supply chains that are competing.’

In this world of transformation Supply chain elements has become the hottest buzzword of this decade. It is very important for smooth functioning in an organization. In commerce, supply chain management, management of the flow of goods and services between business and their location includes the movement and storage of raw materials of work in process inventory and of finished goods. As well as to end order fulfillment from the point of view of origin to point of consumption.

Elements of supply chain management is useful for the both manufacturer as well as their suppliers. Thus, The manufacturer can increase the profit margin by rightly knowing the demand for the product in the market where as a supplier can manage his supplies effectively to different manufacturers as we get communicated with the need for the material on time.

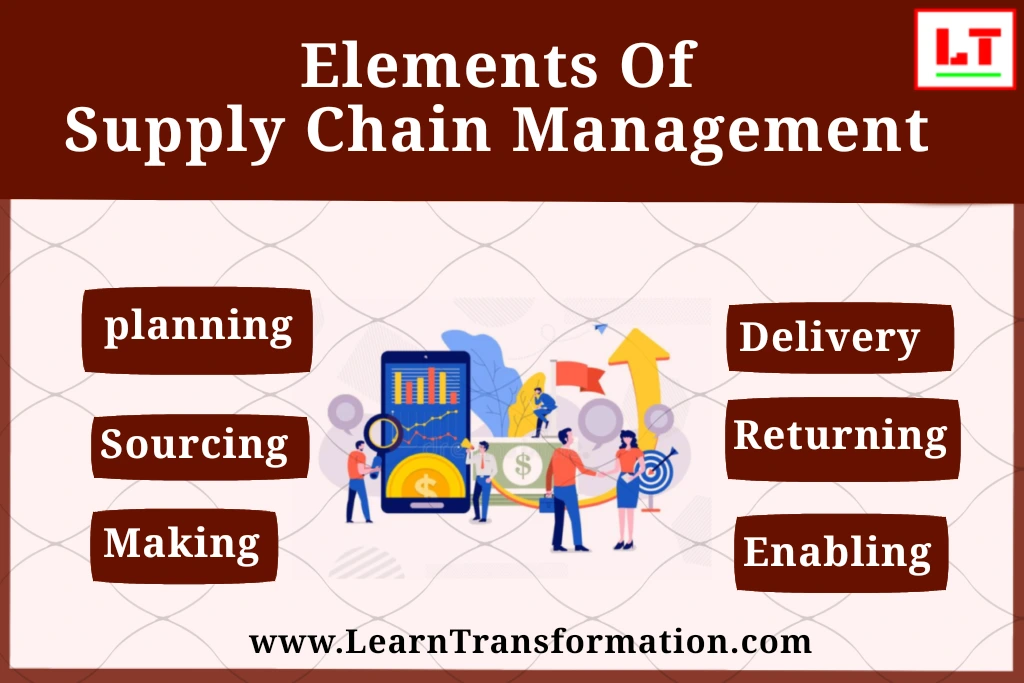

A supply chain management strategy is very essential in business nowadays because, It helps in improving the operations, increasing levels of outsourcing, it increases transportation costs, competitive price pressures, etc. So now, Let us see the components of supply chain management

What are the 6 elements of supply chain management ?

‘ It is not the Organizations that are competing, it’s a supply chains that are competing.’

In this world of transformation Supply chain has become the hottest buzzword of this decade. It is very important for smooth functioning in an organization. In commerce, supply chain management, management of the flow of goods and services between business and their location includes the movement and storage of raw materials of work in process inventory and of finished goods. As well as to end order fulfillment from the point of view of origin to point of consumption.

Supply chain management is useful for the both manufacturer as well as their suppliers. Hence, The manufacturer can increase the profit margin by rightly knowing the demand for the product in the market where as a supplier can manage his supplies effectively to different manufacturers as we get communicated with the need for the material on time.

Leader’s Tip

Encourage open lines of communication and collaboration among all supply chain roles to guarantee consistent performance and minimise disruptions.

This supply chain management strategy is very essential in business nowadays because, It helps in improving the operations, increasing levels of outsourcing, it increases transportation costs, competitive price pressures, etc. Let us see the components of it.

Hand picked for you – how organizations are using supply chain management in their daily use

PLANNING

Planning is the first and the foremost essential element of the supply chain . The purpose of planning component is to manage and plan all required resources in the organization to produce goods and services. Planning is not just one activity, it is a whole specter of them, and it just starts with this decision. Whether to manufacture the components yourself or to buy them from a supplier. This is this decision needs to be made carefully. But even when you opt for one or the other, there are still nuisance for each choice. Will you manufacture it domestically or internationally by domestically or internationally? Make goods stock or to order. So all these decisions are made wisely in this step.

SOURCING

The second component is sourcing. Departments of an organization largely depend on its suppliers. It is essential job of an organization to choose the right suppliers to deliver the material and services that it requires to produce final products. Organization gets into a contract with the suppliers and suppliers, provide products and services to the organization. So sourcing has various methods and organization uses different ways to manage its relationship with the suppliers.

The main processes which are part of social sourcing includes ordering material, receiving material management of inventory, keeping communication with the suppliers and authorizing suppliers payment.

MAKING

The next component is making component that is the responsibility of the supplier chain manager to coordinate the activities of production. Various activities are part of supply chain management process. For example ; accepting raw material, manufacturing products, testing the quality of final products, discarding and recycling the stuff that does not match the quality standards, packaging the final product and scheduling the final delivery.

DELIVERY

The delivery component of supply chain management is also famous as logistics. The delivery process is complex and people choose their products influenced by the quality and the speed of the delivery.

It consists of activities like coordinating customers, orders, scheduling, delivery, method of payment, dispatching, deliveries, invoicing, customers and receiving the payments. Many business firms outsource their delivery work to the specialized organizations to reduce their workload and in case when the delivery process requires special handling and extra effort.

Leader’s Tip

Leverage tools like data analytics and technological advancements to boost efficiency, effectiveness, and innovation.

RETURNING

This is the word that no business owner wants to hear Return of goods. Yet sometimes we can’t escape from the reality.

In this step, the organization returns the unwanted, defective or excess quantity. Good back to the supplier. The supplier should take back the products and scrap or recycle the faulty products in case they receive products or surplus in volume but in good shape then it should be returned to the warehouse for sale.

ENABLING

Supply chain requires different support process to keep a check on the information following through the supply chain process. Supply chain management should abide by the regulations . The methods like human resources, finance, IT, portfolio management and sales are essential process of enabling processes.

So these were the components of SCM. You will be able to accomplish those tasks of supply chain management that we talked about by following all these components.

Check out the video-

Faqs

What are the elements of supply chain management?

PLANNING , SOURCING , MAKING , DELIVERY, RETURNING, ENABLING

What are the 6 components of the supply chain?

Elements of supply chain management is useful for the both manufacturer as well as their suppliers. The manufacturer can increase the profit margin by rightly knowing the demand for the product in the market where as a supplier can manage his supplies effectively to different manufacturers as we get communicated with the need for the material on time.

Key Takeaways

- Demand forecasting and inventory management are key to running an efficient business.

- Procurement and sourcing: picking dependable vendors and forging close bonds to guarantee timely, cost-effective purchases.

- Manufacturing and operations: Streamlining production and maximising resources to effectively satisfy client needs.

- Logistics and transportation: effectively managing shipping, storage, and distribution to lessen overhead and shorten turnaround times.

- Managing inventory involves keeping just enough stock on hand to fulfil orders while keeping overhead to a minimum.

- Risk management, or the procedure of anticipatorily locating and eliminating threats to the security and smooth operation of a company’s supply chain.