Logistics is the ball and chain of armored warfare. –Heinz Guderian

The success of a corporation depends on its supply chain operations. Your supply chain can run more quickly and effectively the better the business outcome.

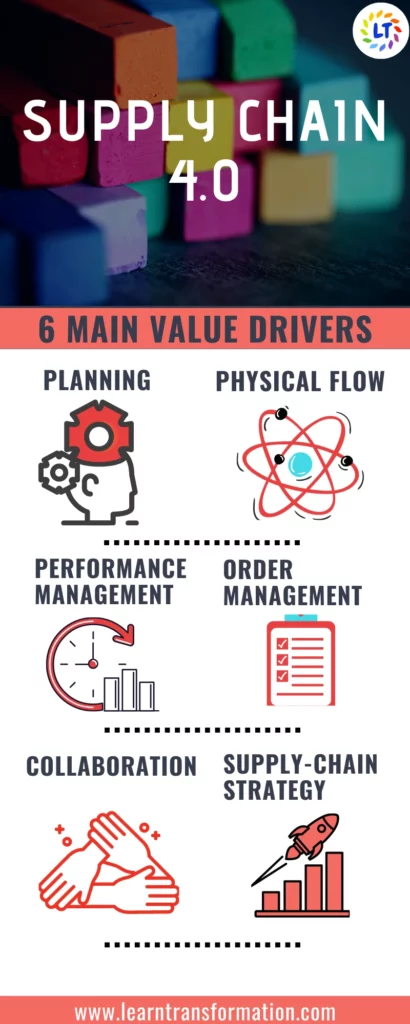

The field of supply chain management is witnessing a tremendous transition in today’s hectic global economy. This transformation is being propelled by a steadfast dedication to improving efficiency, agility, and sustainability, all of which are essential for remaining competitive in a world that is becoming more linked. Supply Chain 4.0, a paradigm change that embraces the power of digital technology to create smarter, more connected, and highly responsive supply chains, is at the forefront of this revolution. We set out on an exploration of Supply Chain 4.0 and the six main supply chain value drivers that are changing the face of logistics, production, and distribution in this blog.

- Data Analytics and Predictive Insights in Supply Chain 4.0: A Key Supply Chain Value Driver

- IoT (Internet of Things) and Real-time Monitoring in Supply Chain 4.0: A Pioneering Supply Chain Value Driver

- Automation and Robotics in Supply Chain 4.0: The Vanguard Supply Chain Value Driver

- Blockchain and Transparency in Supply Chain 4.0: A Pioneering Supply Chain Value Drive

- Artificial Intelligence (AI) and Machine Learning in Supply Chain 4.0: The Cognitive Supply Chain Value Driver

- Collaborative Ecosystems in Supply Chain 4.0: The Synergistic Supply Chain Value Driver

- 5 Best Supply Chain 4.0 Books

These value drivers are the foundation of supply chain 4.0, launching businesses into a future of unheard-of innovation and effectiveness. Let’s examine each of these factors in more detail to learn how they are changing the market and posing both opportunities and problems.

Data Analytics and Predictive Insights in Supply Chain 4.0: A Key Supply Chain Value Driver

Data analytics and predictive insights are the fundamental pillars of the Supply Chain 4.0 era, enabling transformation in every area of the supply chain. This value driver enables businesses to take well-informed, data-driven decisions that improve productivity, streamline processes, and ultimately provide better customer experiences. In this article, we examine how predictive insights and data analytics are changing supply chain management.

Data’s Influence in Supply Chain 4.0

Data is everywhere in the intricate supply systems of today. With the use of this data, Supply Chain 4.0 is able to obtain a thorough insight of operations, consumer behaviour, and market trends. Aggregating, processing, and analysing this data allows organisations to gain previously unattainable insights.

1. Increased transparency and visibility

The extraordinary visibility that data analytics provides is one of its main advantages. Thus, real-time tracking of inventory levels, manufacturing procedures, and shipping routes is made possible by Supply Chain 4.0. Because of this openness, bottlenecks, inefficiencies, or deviations from the plan can be quickly found. As a result, businesses can take preemptive steps to address problems, reducing disruptions and enhancing supply chain efficiency.

2. Demand Prediction Driven by Data

Predictive analytics expands on data by precisely predicting future demand. Additionally, traditional supply chains frequently struggle with problems like overstock or stockouts, which leads to financial losses and dissatisfied customers. In order to more accurately estimate demand, supply chain 4.0 makes use of historical data, industry patterns, and even external elements (such weather or social media trends). As a result, businesses are able to reduce carrying costs while increasing product availability and optimising inventory levels.

3. Cost-saving measures and operational effectiveness

Data-driven insights cover the full ecosystem of the supply chain. Furthermore, companies can find chances for increasing efficiency by looking at data from manufacturing lines, warehouses, and distribution centres. Data analytics contributes to significant cost savings, a key component of supply chain value, whether it is through the optimisation of manufacturing schedules, expediting order fulfilment, or lowering energy use.

Data analytics and predictive insights are the fuel that propel intelligent, effective, and customer-focused supply networks in Supply Chain 4.0. Thus, organisations can obtain increased visibility, operational excellence, cost savings, and environmental sustainability by utilising the amount of data available. Those that embrace and master the art of data analytics will unquestionably be at the forefront of supply chain innovation and value generation as technology advances and data becomes increasingly more available.

IoT (Internet of Things) and Real-time Monitoring in Supply Chain 4.0: A Pioneering Supply Chain Value Driver

The Internet of Things (IoT) and real-time monitoring have emerged as crucial value drivers that are revolutionising supply chain management in the dynamic environment of Supply Chain 4.0. Additionally, these technologies play a key role in enabling supply chains to operate with unparalleled visibility, agility, and reactivity. In this section, we explore the crucial part that IoT and real-time monitoring have played in transforming the ecology of the supply chain.

Also read: Supply Chain 4.0 And Logistics 4.0 – The Major Difference

Supply Chain 4.0’s Connected IoT World

The Internet of Things (IoT) is a network of talkative, data-exchanging physical items, gadgets, and sensors. Hence, this technology is used in Supply Chain 4.0 to gather, transmit, and analyse real-time data from numerous touchpoints throughout the supply chain. Observe how IoT and real-time monitoring are enhancing the value of the supply chain:

1. Instantaneous visibility

Supply Chain 4.0’s eyes and ears are IoT sensors and devices, which offer real-time visibility into all facets of the supply chain. Additionally, these sensors continuously track factors like temperature, humidity, location, and even product integrity from the manufacturing floor to transportation vehicles and distribution centers. Furthermore, the instantaneous transmission of this data to centralised platforms gives stakeholders total visibility into business processes.

2. Proactive Problem Solving

Supply chain managers can spot and resolve issues as they appear with real-time monitoring. IoT sensors, for instance, can provide alerts when storage conditions for a temperature-sensitive product fall outside of acceptable bounds while being transported. Thus, this enables quick corrective action to maintain product integrity and quality, avoiding expensive losses, and upholding consumer confidence.

3. Increased Resource Utilisation

Organisations may maximise asset utilisation with the help of IoT. For instance, businesses may monitor the whereabouts and utilisation of the transportation vehicles they use, guaranteeing effective scheduling and routing. By enhancing routes and using less fuel, this not only lowers transport costs but also has a minimal negative impact on the environment.

A paradigm shift from reactive to proactive supply chain management is being driven by IoT and real-time monitoring in Supply Chain 4.0. These technologies give businesses the ability to adapt quickly to changing circumstances, allocate resources efficiently, improve product quality, and cut costs at the same time. Companies can transform their supply chains into flexible, resilient ecosystems that offer great value to both themselves and their clients by utilising the real-time data created by IoT. Thus, the significance of supply chain management in influencing the direction of logistics and distribution will only get more important as the IoT landscape develops.

Leader’s Tip

Invest in data analytics tools and talent to harness the power of data for informed decision-making.

Automation and Robotics in Supply Chain 4.0: The Vanguard Supply Chain Value Driver

Automation and robots are revolutionary forces that are transforming the logistics, manufacturing, and distribution scene in the Supply Chain 4.0 age. Supply chains are being propelled by these technologies to previously unheard-of levels of efficiency, speed, and adaptability. We explore the deep effects of automation and robots as the key value generators in Supply Chain 4.0 in this section.

The Development of Robotics and Automation

Supply Chain 4.0 is aware of how automation and robotics have the ability to enhance human abilities and completely transform the way commodities are created, stored, and distributed. Furthermore, the value that these technologies add to the supply chain is as follows:

- Improved operational effectiveness

By automating labor-intensive and repetitive tasks, automation and robotics optimise supply chain operations. Robots are remarkably fast and accurate at picking, packing, and sorting items in warehouses. This efficiency results in decreased labour costs, shortened lead times, and higher throughput, providing organisations with real savings.

2. Accurate Quality Assurance

Robotic systems with cutting-edge sensors can carry out in-depth product quality controls. They have the ability to find flaws, oddities, or discrepancies that human inspectors might miss. Automation greatly increases the value of the supply chain by maintaining product quality, which also lowers waste, minimises recalls, and upholds brand reputation.

3. Self-driving vehicles

Autonomous vehicles, such as self-driving trucks and drones, are becoming more common in the transportation sector. These cars drive precisely, following the rules of the road, and planning the best routes. By eliminating the need for human drivers, they lower labour costs while improving safety and enabling round-the-clock delivery.

Automation and robots are more than just tools in Supply Chain 4.0; they are catalysts for change. These technologies promote cost reduction, agility, and operational excellence. They improve quality control, permit 24-hour operations, and offer the information required for well-informed decision-making. Automation and robots’ impact on the supply chain will only grow as they advance, making them essential drivers of supply chain value in a corporate environment that is becoming more competitive and dynamic.

Blockchain and Transparency in Supply Chain 4.0: A Pioneering Supply Chain Value Drive

Blockchain technology is embraced by Supply Chain 4.0 as a ground-breaking tool for building transparency, traceability, and trust throughout the supply chain. In addition to guaranteeing data integrity, this disruptive value driver also strengthens security, lowers fraud, and increases compliance. This section looks at how Supply Chain 4.0 is changing as a result of blockchain technology.

Also read: How Logistics 4.0 And Supply Chain 4.0 Will Increase Efficiency By 5x?

Blockchain’s Function in Supply Chain 4.0

Blockchain is a distributed, unchangeable ledger that keeps track of data and transactions over a network of computers. Additionally, blockchain acts as the digital foundation of Supply Chain 4.0, enabling safe, open, and unchangeable record-keeping. As an example of how blockchain adds value to the supply chain:

1. Improved Traceability and Transparency

Every transaction and event in the supply chain is permanently recorded on the distributed ledger of the blockchain. Every stage of the process, from the source of raw materials to the location of the finished goods, is openly recorded. By enabling real-time monitoring and verification, this traceability lowers the possibility of fraud, forgery, and supply chain inconsistencies.

2. Enhanced Safety

To secure data, blockchain uses cryptographic methods. This implies that once a transaction has been recorded, it cannot be changed or removed without the agreement of other network users. Sensitive supply chain data is protected from data breaches by this level of protection, ensuring that it is kept private and unaltered.

3. Simplified Audits and Compliance

Compliance with industry norms and regulations is made simpler by blockchain’s transparency and immutability. Additionally, by giving auditors access to blockchain records, businesses can simply show compliance with quality, safety, and environmental regulations. Further, this makes audits more efficient, lowers the cost of compliance, and ensures regulatory compliance.

Blockchain technology is the foundation for transparency, trust, and integrity in Supply Chain 4.0. Additionally, it deals with important topics like cooperation, traceability, security, and compliance. Its acceptance will only grow as more businesses come to understand blockchain’s transformational potential. The impact of blockchain on the supply chain goes far beyond technology; it is a catalyst for creating ecosystems that are robust, secure, and transparent and that provide real value to both businesses and consumers.

Artificial Intelligence (AI) and Machine Learning in Supply Chain 4.0: The Cognitive Supply Chain Value Driver

AI and ML drive future-ready, insightful supply chains. Further, tech revolutionizes supply chain management, adding value. Here, we examine how AI and ML are changing the landscape of the supply chain.

The Brains of Supply Chain 4.0: AI and ML

Supply Chain 4.0 acknowledges AI and ML as potent technologies that transform data into valuable insights, automate processes, and enhance decision-making. The following are the main ways that AI and ML add value to the supply chain:

1. Making Decisions Based on Data

AI and ML systems analyze massive amounts of data from various sources, such as IoT devices, historical records, and external influences. Additionally, supply chain managers may make more informed, precise, and fast decisions thanks to this data-driven methodology. Thus, AI-powered demand forecasting optimizes inventory levels, lowers carrying costs, and prevents stockouts and overstock conditions.

2. Predictive Maintenance

By examining sensor data, ML systems can forecast equipment breakdowns or the need for repair. By minimising downtime, lowering repair costs, and ensuring that gear runs as efficiently as possible, this predictive maintenance strategy enhances the supply chain’s overall resilience.

3. Route Improvement

The most economical and efficient routes for transportation are found via AI-driven algorithms for route optimisation. Furthermore, these algorithms save transportation costs, increase delivery times, and minimise environmental effect by taking factors like traffic conditions, fuel prices, and delivery windows into account.

The cognitive engines behind innovation, efficiency, and adaptation in Supply Chain 4.0 are AI and ML. These tools simplify decision-making, translate data into useful insights, and enhance supply chain operations. As AI and ML develop, their influence on the supply chain will only grow, making them essential drivers of supply chain value in a business environment that is becoming more complicated and competitive. Businesses that adopt AI and ML will be well-positioned to prosper during the Supply Chain 4.0 era.

Collaborative Ecosystems in Supply Chain 4.0: The Synergistic Supply Chain Value Driver

Supply Chain 4.0 acknowledges the importance of collaborative ecosystems as a fundamental value generator that cuts over conventional lines. In the modern day, data exchange and networked partnerships are the key to achieving excellence in the supply chain. Thus, ecosystems that encourage collaboration between partners, customers, and suppliers are revolutionising the way that supply chains operate. Here, we explore how Supply Chain 4.0’s collaborative ecosystems create value.

Adaptive Collaborative Ecosystem Dynamics

Supply Chain 4.0 uses collaborative ecosystems to connect stakeholders in a network where information is shared freely and choices are made as a group. The following are the main ways that collaborative ecosystems enhance the value of the supply chain:

Leader’s Tip

Evaluate the potential of blockchain for supply chain transparency and traceability.

1. Decision-Making in Real Time

Supply chain partners can exchange real-time information thanks to collaborative ecosystems. Real-time visibility aids faster, informed decisions. Additionally, this improves market responsiveness, reducing lead times, boosting satisfaction.

2. Demand Synchronisation

Demand synchronisation is a crucial element of Supply Chain 4.0. Suppliers are able to get real-time demand indications from customers because to collaborative ecosystems. Additionally, this reduces the possibility of overproduction or stockouts by ensuring that production is in line with actual customer needs.

3. Complete visibility

Ecosystems that collaborate provide complete supply chain visibility.Stakeholders track product progress from source to users. This transparency increases the supply chain’s resilience and minimizes interruptions.

Supply Chain 4.0 fosters collaboration among diverse participants. These ecosystems make real-time decision-making, demand synchronization, end-to-end visibility, and risk reduction possible. Furthermore, the role of these ecosystems in generating supply chain value will only grow as businesses continue to value collaboration. Embracing collaborative ecosystems leads to supply chain innovation.

5 Best Supply Chain 4.0 Books

Global Reader’s Click Below:

- Starting a Business QuickStart Guide: The Simplified Beginner’s Guide to Launching a Successful Small Business, Turning Your Vision into Reality, and Achieving Your Entrepreneurial Dream

- Operations and Supply Chain Management Essentials You Always Wanted to Know (Self-Learning Management Series)

- The Supply Chain Revolution: Innovative Sourcing and Logistics for a Fiercely Competitive World

- Business Basics BootCamp: The Ultimate Crash Course

- Discrimination and Disparities

India Reader’s Click below:

- Operations Management: Processes and supply chain | Twelfth Edition | By Pearson

- Designing & Managing the Supply Chain

- Digital Supply Networks

- Supply Chain Management | By Pearson

- Operations and Supply Chain Management

Conclusion

Companies may optimise their supply chain operations, cut costs, boost customer satisfaction, and respond to a constantly shifting business environment by utilising these drivers. Thus, embracing Supply Chain 4.0 is a strategic necessity for businesses that want to succeed in a fiercely competitive global market, not just a technology advancement. Additionally, by integrating digital technology, Supply Chain 4.0 is transforming the landscape of supply chain management and unleashing new levels of productivity, adaptability, and sustainability. The six primary supply chain value drivers covered in this article are driving this revolution: data analytics, IoT, automation, blockchain, AI, and collaborative ecosystems. Thus, organizations effectively utilizing these value drivers will position themselves best to achieve supply chain excellence, spur innovation, and establish long-lasting competitive advantages as Supply Chain 4.0 continues to develop. Digital supply chain management is now the way of the future.

Key Takeaways

- Leveraging data enhances supply chain understanding, optimization, cost savings, service.

- IoT enhances real-time visibility, tracking, equipment health, efficiency, and satisfaction.

- Automation, robotics cut costs, boost efficiency, reduce lead times, competitiveness.

FAQs

What is a supply chain 4.0?

Supply Chain 4.0, a paradigm change that embraces the power of digital technology to create smarter, more connected, and highly responsive supply chains, is at the forefront of this revolution

How will supply chain 4.0 impact all areas in supply chain management?

By integrating digital technology, Supply Chain 4.0 is transforming the landscape of supply chain management and unleashing new levels of productivity, adaptability, and sustainability. This revolution is being driven by the six primary supply chain value drivers that were covered in this article: data analytics, IoT, automation, blockchain, AI, and collaborative ecosystems

Also check out: