Logistics is the ball and chain of armored warfare.

Heinz Guderian

Warehousing

Warehouse plays a key role in supply chain management, providing a central location for inventory management, order fulfillment, and logistics operations.

Key warehousing activities include inventory management, picking and packing, inventory optimization, and efficient logistics. Additionally, effective warehousing practices focus on maximizing space utilization, ensuring inventory accuracy, streamlining workflows, and implementing appropriate security measures. Modern warehouse management often incorporates technologies such as warehouse management systems (WMS) to increase efficiency, track inventory movements, and improve overall operational performance.

The use of 3PL logistics makes it possible to handle both inbound and outbound cargo, distribute a wide range of raw materials and completed goods, integrate freight and customs, properly manage hauls to customers, and fulfill orders to the highest standard.

Enterprise supply chains can benefit from 3PL providers’ complete, sometimes one-stop solutions for packaging, warehousing, transportation, and order fulfillment. Your supply chain may have gaps that 3PLs may find and close.

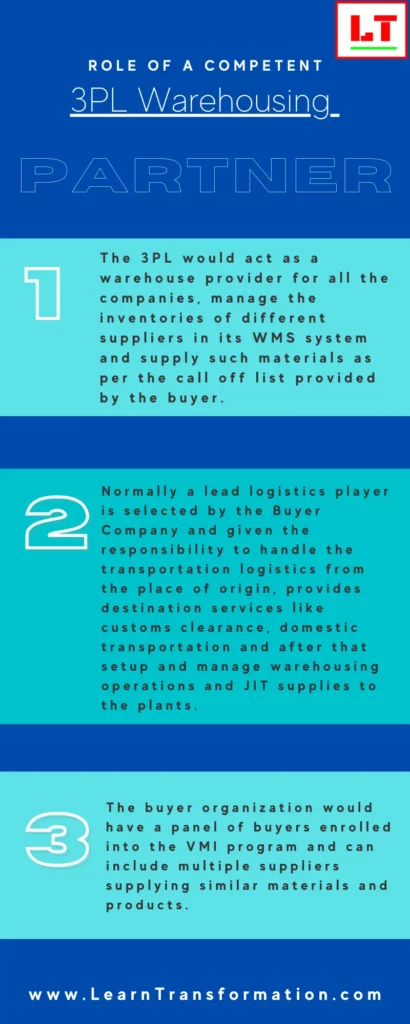

The following are some important tasks that a capable 3PL warehouse supplier can complete:

- Effective inventory management and storage: Professional 3PL warehouse companies excel in efficiently managing and arranging inventory inside of their facilities. Furthermore, they use cutting-edge warehouse management systems (WMS) to keep track of stock levels, put effective storage plans into place, and guarantee precise inventory counts. This increases overall operational efficiency, decreases stockouts, and improves inventory accuracy.

- Order fulfilment and distribution: 3PL warehouse companies are in charge of accurately and promptly completing customer orders. Additionally, they take orders, choose the products from the inventory, properly package them, and get them ready to dispatch. Moreover, competent suppliers have enhanced customer satisfaction by streamlining procedures and training workers to complete orders accurately and promptly.

- Value-added services: A lot of reliable 3PL warehouse companies give value-added services in addition to standard storage and distribution. Kitting and assembly, labelling and packaging, customising, product inspection, quality control, and reverse logistics are a few of these services that may be offered. Thus, by providing these extra services, the supplier enhances the value of the supply chain and helps companies meet particular consumer requirements.

- Transportation management: Reputable 3PL companies frequently provide transportation management services in addition to warehousing. Hence, to ensure the delivery of items from the warehouse to their final locations, they have formed agreements with carriers, freight forwarders, and logistics service providers. This integrated strategy aids in streamlining the entire supply chain, cutting expenses associated with transportation while increasing delivery accuracy and speed.

Leader’s Tip

Before Looking for a 3PL Warehousing Partner, Be Clear About Your Warehousing Needs. Know the items you need to keep, how much of each you need to, how to handle them, and whether you need any specialised services, such as handling hazardous materials or temperature-controlled storage.

Managing supply chains effectively is becoming more and more difficult for businesses in the modern, continuously evolving business environment. Supply chain management’s logistics and warehousing components are especially important since they have a direct impact on customer satisfaction, cost containment, and overall competitiveness. Many companies use Third-Party Logistics (3PL) providers for their warehousing needs in order to overcome these difficulties. This article examines the function of skilled 3PL warehousing in contemporary supply chains, stressing its advantages and important factors.

Supply Chain Management’s Evolution

From its early days of straightforward inventory management and transportation, supply chain management has advanced significantly. In the past, businesses frequently managed the whole supply chain internally, from manufacture to distribution. The supply chain environment did, however, become more intricate and interwoven as businesses became more globalised, consumer expectations increased, and technology advanced.

The field of supply chain management today encompasses many different aspects, including planning, purchasing, production, inventory control, logistics, and distribution. Additionally, all relevant parties, including suppliers, manufacturers, distributors, and retailers, must work in seamless synchronisation. Businesses increasingly rely on specialised partners, such as 3PL providers, to effectively meet these needs.

Third-Party Logistics (3PL): An Overview

Third-Party logistical, or 3PL, is the practise of contracting out certain supply chain and logistical tasks to outside service providers. Furthermore, these tasks may include delivery, distribution, order fulfilment, and transportation. Experts in logistics and supply chain management, 3PL providers sell their services to companies looking to streamline their processes and boost productivity.

Also read: Understanding 3PL And Why It Is Beneficial For Your Business?

What a 3PL Warehouse Does?

Modern supply chain management must include warehousing as a vital element. It entails managing, distributing, and storing goods and inventory.Thus, a key component of guaranteeing the efficient movement of commodities through the supply chain is competent 3PL warehousing. The main functions and advantages of 3PL warehousing are as follows:

- Cost-effectiveness: 3PL companies frequently have enormous networks of warehouses, which enables them to realise economies of scale. Businesses can benefit from shared storage space, labour, and equipment expenditures, which results in cost savings for them.

- Scalability: Reliable 3PL warehousing provides scalability to accommodate changing demand. Without making substantial capital investments, businesses can modify their storage needs in response to seasonal variations or shifts in market demand.

- Focus on Core strengths: Businesses can concentrate on their core strengths by outsourcing warehousing tasks to a 3PL supplier. They can devote time and energy on marketing, product development, and other strategic endeavours while outsourcing logistics and storage work to professionals.

- Modern Technology: A lot of 3PL companies make investments in cutting-edge inventory tracking and warehouse management systems (WMS). These methods improve warehouse efficiency overall as well as inventory accuracy and order fulfilment speed.

- Knowledge: 3PL warehouse companies are experts in inventory control, order picking, packing, and shipping. To streamline warehouse operations, they bring industry best practises.

- Reduced Risk: Working with a 3PL provider can assist reduce warehousing-related risks such inventory loss, damage, and compliance problems. Providers frequently have effective quality control procedures and security safeguards in place.

- Global Reach: 3PL warehousing can give companies access to a worldwide network of storage facilities if they have international operations or goals. As a result, shipment lead times are shortened and worldwide distribution is made more effective.

- Flexibility: Reputable 3PL storage companies give flexible solutions that are catered to the specific requirements of each company. They can adjust to your needs whether you need shared warehousing, dedicated warehousing, or a combination of both.

- Order fulfilment: Quicker and more accurate order fulfilment increases customer happiness and loyalty. This is made possible by efficient warehousing. Complex order fulfilment procedures are expertly managed by 3PL suppliers.

- Inventory Optimisation: 3PL warehouse companies can help companies manage their stock levels. They assist in reducing carrying costs while assuring product availability by analysing demand patterns and putting inventory control techniques into place.

Leader’s Tip

Seek a 3PL provider with knowledge of your sector. Understanding particular issues, regulatory needs, and best practises can be aided by industry-specific information.

Role of a competent 3PL warehouse

Businesses are always looking for methods to improve customer happiness, cut costs, and streamline operations in the dynamic world of logistics and supply chain management. Partnering with a capable Third-Party Logistics (3PL) warehouse is a crucial strategy that has proven to be very beneficial. Let’s explore the crucial significance a capable 3PL warehouse plays in the prosperity of contemporary organisations.

1. Specialisation and Expertise:

A 3PL warehouse that is capable offers a plethora of sector-specific knowledge. Whether you work with perishable goods, fragile things, or specialised handling demands, they are aware of the particular issues and needs your firm faces. Your inventory will be handled with care and precision thanks to our experience.

2. Scalability and Flexibility

Companies need a logistics partner that can grow with them, especially those that are undergoing growth. Scalability is a feature that competent 3PL warehouses offer to accommodate shifting inventory levels, seasonal variations, and unforeseen spikes in demand. This adaptability is crucial for preserving effective operations.Modern supply chains heavily rely on technology for efficiency and visibility.

3. State-of-the-art Technology

A capable 3PL warehouse makes investments in cutting-edge inventory tracking software and Warehouse Management Systems (WMS). Better decision-making is made possible by these technologies’ real-time insights on inventory levels, order statuses, and shipment information.

4. Inventory Accuracy and Control

The foundation of a good supply chain is accurate inventory management. Stockouts, overstocking, and inconsistencies are less likely to occur in competent 3PL facilities since they implement strict inventory management procedures. By doing this, you may satisfy client demand while reducing carrying expenses.

5. Effective Order Fulfilment

A capable 3PL warehouse prides itself on timely and precise order fulfilment. To shorten cycle times and improve customer satisfaction, they optimise the order selection, packing, and shipping operations. This effectiveness results in quicker shipment timeframes and fewer shipping mistakes.

6. Cost Savings

Skilled 3PL warehouses are excellent at identifying areas of your supply chain where money may be saved. They let you make well-informed decisions regarding inventory levels and improve transportation routes while lowering storage expenses in warehouses. Your bottom line may be greatly impacted by these expense savings.

Also read:Best Supply Chain Management Interview with Mohammad Iqbal – The Best Ever in Supply Chain Domain

7. Risk Reduction

Disruptions to your supply chain can be expensive and harm your brand. Strong risk mitigation techniques, such as disaster recovery plans, insurance coverage, and security procedures, are implemented by competent 3PL warehouses. Thus, unexpected occurrences are guarded against in your inventory.

8. Value-Added Services

In addition to the essentials, a lot of capable 3PL warehouses provide value-added services like kitting, labelling, quality control, and returns management. These services can improve your total client offering while further streamlining your supply chain.

9. Focus on Core strengths

Your company may concentrate on its core strengths, such as product development, marketing, or customer service, by outsourcing warehousing and logistics tasks to a reputable 3PL warehouse. This emphasis on strengths can stimulate innovation and development.

5 Best 3PL Logistics Transformation Books

Global Reader’s Click Below:

- Arriving Today: From Factory to Front Door — Why Everything Has Changed About How and What We Buy

- Supply Chain Management For Dummies

- Warehouse Management: The Definitive Guide to Improving Efficiency and Minimizing Costs in the Modern Warehouse 4th Edition

- Extreme Ownership: How U.S. Navy SEALs Lead and Win (New Edition)

- The 7 Habits of Highly Effective People: Habit Tracker

India Reader’s Click below:

- Business Strategy Essentials You Always Wanted To Know (Second Edition) (Self-Learning Management Series)

- 7 Powers: The Foundations of Business Strategy

- Your Next Five Moves: Master The Art of Business Strategy

- Leadership Essentials You Always Wanted to Know (Self-Learning Management Series)

- The 5 Levels Of Leadership : Proven Steps To Maximize Your Potential

Conclusion

In conclusion, a capable 3PL warehouse is more than just a service provider; it is a strategic partner that has the power to make or break the effectiveness of your supply chain and customer happiness. Businesses may succeed in today’s cutthroat industry thanks to their knowledge, technology, scalability, and dedication to excellence. To guarantee that your supply chain continues to be a source of strength and competitive advantage, give priority to competency, industry knowledge, and a successful track record when choosing a 3PL partner.

Key Takeaways

- A capable 3PL warehouse can handle the particular issues and demands of your organisation because they have industry-specific knowledge and experience.

- A reliable 3PL partner will have the capacity to scale operations up or down as necessary and adjust to shifting conditions.

- Technology is essential to the efficiency and visibility of modern supply networks. A capable 3PL warehouse makes investments in cutting-edge inventory tracking software and Warehouse Management Systems (WMS).

FAQs

What is a 3PL warehouse?

Modern supply chain management must include warehousing as a vital element. It entails managing, distributing, and storing goods and inventory. A key component of guaranteeing the efficient movement of commodities through the supply chain is competent 3PL warehousing.

Why is 3PL a good solution for supply chain management?

3PL companies frequently have enormous networks of warehouses, which enables them to realise economies of scale. Businesses can benefit from shared storage space, labour, and equipment expenditures, which results in cost savings for them.

Also check out: