Deep learning will revolutionize supply chain automation

Dave Waters

Digital Transformation is one of the most essential business trends of our time. Digital supply chains & digitization of business processes in general, have a huge impact on business success. So, In the area of digital Supply Chain, which truly spans the whole operations of most any company. Technologies like artificial intelligence, big data provide the platform to completely reevaluate how the work of Supply Chain is conducted every minute of every day. In some regards, the imperious to follow Digital Transformation is even more important in light of the pandemic and its consequences.

There is a massive change coming to the supply chain. How will Supply Chain Transformation modify the manner you do business? Is your business enterprise Future ready? In the time characterized by high volatility, complexity & high technology developments, digitalization of the supply chain is an evasive goal. With the options that digital technologies provide to develop new business models. Companies that combine digital technologies into their supply chain can unexpectedly enhance service levels whilst reducing prices as much as 30%. So, Reset it with digital manufacturing to respond quicker to market demand.

For some traditional industries, digital supply chain transformation is still an unknown part of an overall business innovation. The root cause of the struggle that many supply chains have with digital transformation begins with a key word “transformation”. That’s generally overlooked or misinterpreted. Moreover, It means a notable large-scale change that aligns the organization in a new direction. Not an incremental improvement or transition to a new system. So, Unfortunately, many organizations aren’t commencing on true transformation. Rather, they’re solving discrete business problems with digital technologies by generating one-off solutions, instead embracing an integrated approach to addressing several problems.

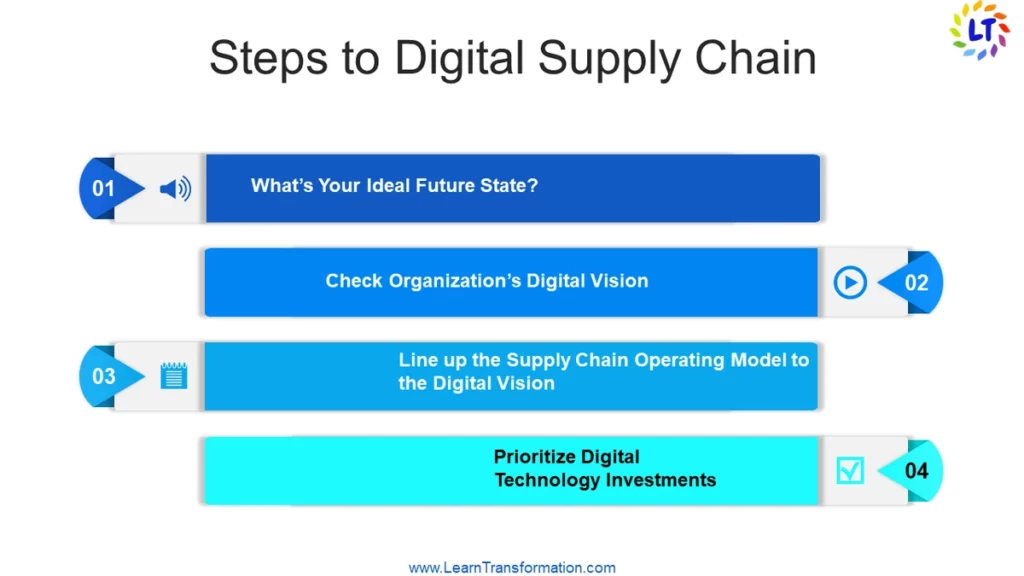

What are Steps to Digital Supply Chain?

Digital Supply Chain:

The application of the Internet of Things & advanced analytics of big data, the utility of advanced robotics in digital supply chain management: place sensors in everything, create networks everywhere, automate anything & evaluate everything to notably enhance overall performance & customer satisfaction.

Leader’s Tip:

Adopt cutting-edge technologies like IoT, AI, and blockchain to optimize supply chain operations as you embrace digital transformation.

1. What’s Your Ideal Future State?

Also Read: What Is 3PL and How Will It Benefit Your Business?

The key to building supply chain 4.0 – the next-generation digital supply chain with a view to be competitive in 5 or may be 10 years is predicting change. So, Leaders evaluate where the industry is going & identify the supply chain capabilities they require to get there.

Successful companies keep away from incremental actions by visualizing simply how severe the future for supply chain transformation may look. For instance, what could happen if the whole business shifted from extreme margin to low margin or if it shifted from standard products to custom products? These situations can help supply chain teams discover what the company could want to do in another way and what new abilities this kind of changes could demand.

2. Check Organization’s Digital Vision

Breaking out of silos & agreeing to a digital transformation vision across the complete organization must be the beginning point. So, This is the motivation for action, where you define with other leaders a vision for the type of experience you want your organization to deliver to its customers and identify the capabilities required to deliver it.

Search for those supply chain technologies which have the potential to open new revenue streams and get buy-in and participation across the business.

3. Line up the Supply Chain Operating Model to the Digital Vision

To deliver on digital business priorities, the digital twin supply chain must change. For instance, a product manufacturer’s business priority might be to make sure that a customer’s equipment never stops working. Rather than simply responding to spare parts orders, it must predict possible failure and arrange spare parts supply and service across a partner ecosystem to prevent downtime. The type of digital technology investments that can deliver these changes in the digitalization of it include:

- Internet of Things (IoT) to measure performance in real time.

- Analytics to forecast failure & automate processes.

- Application program interfaces (APIs) to share data with the partner ecosystem.

Hand-picked for you: Internet of things (IoT) in 21st Century

4. Prioritize Digital Technology Investments

In times of unreliability, supply chain organizations tend to focus on improving existing operations to uplift today’s bottom line and renounce the investments required to support tomorrow’s top line. In many cases, this conservative technique will now no longer align with today’s wider organizational transformation priorities.

To assist an organization which can compete in the future, supply chain leaders should do greater than streamline their operations. So, They should develop the future digital supply chain. Thus, It’s a smart supply chain that makes decisions as it interacts across an ecosystem of digitally connected partners.

Check this: 30 Top non-fiction books of all time

Leader’s Tip:

To safeguard sensitive data and guarantee the integrity of your digital supply chain, invest in strong cybersecurity solutions.

Conclusion

It is a riveting time to be a part of the Supply Chain universe. All of these big technologies mean that there will be exceptional opportunities to shape & participate in the evolution to a Digital Supply Chain World. It’s critical to understand that the transformation toa digital supply chain transcends simply the technological capabilities. Supply Chain professionals will have to develop a different skill set to define & operate the Digital Supply Chain of the future.

Frequently Asked Questions

What is Digital Supply Chain?

The application of the Internet of Things & advanced analytics of big data, the utility of advanced robotics in digital supply chain management: place sensors in everything, create networks everywhere, automate anything & evaluate everything to notably enhance overall performance & customer satisfaction

What’s Your Ideal Future State?

The key to building supply chain 4.0 – the next-generation digital supply chain with a view to be competitive in 5 or may be 10 years is predicting change. Leaders evaluate where the industry is going & identify the supply chain capabilities they require to get there.

Key Takeaways

- The digital supply chain enables organizations to respond to market dynamics by providing actual benefits including enhanced visibility, agility, and efficiency.

- Advanced analytics and predictive capabilities help to optimize inventory management, demand forecasting, and overall supply chain performance.

- Digital platforms support supply chain partner collaboration, which promotes end-to-end transparency and enhances decision-making.